Nanomaterials and nanoparticles have many applications across many fields of study. Today they can be found in various products as well as technologies. Most nanoproducts manufactured on an industrial scale are nanoparticles; however they may also result from manufacturing other materials.

An optimal production and reaction environment is crucial in order to produce particle features with size-dependent characteristics, including particle size, chemical composition, crystallinity and shape. Particle characteristics like particle size can be controlled via temperature, pH-value, concentration concentration chemical composition surface modifications process control.

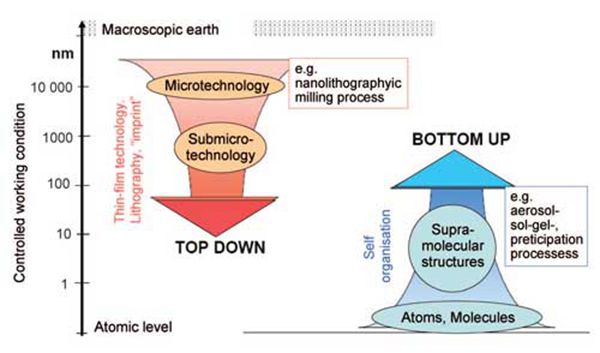

Two strategies are employed in producing nanoparticles: “top-down” and “bottom-up”. Top-down refers to mechanical crushing of source material using milling processes, while in bottom-up structures are built up through chemical reactions; which method should be chosen depends on chemical composition and desired features for nanoparticles.

Top-Down/mechanical-physical production processes “Top-down” refers to mechanical-physical particle production processes based on microsystem technology principles. Traditional mechanical-physical crushing methods for producing nanoparticles involve various milling techniques.

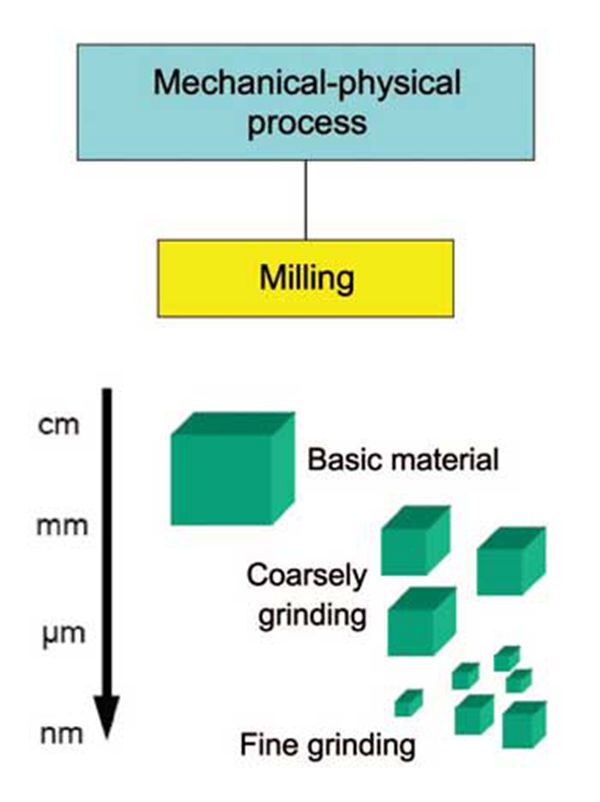

Milling Processes

Mechanical production uses milling to crush microparticles. This technique is widely employed for producing both metallic and ceramic nanomaterials; for metallic nanoparticles specifically, traditional source materials (e.g. metal oxides) may be ground up using high-energy ball mills with grinding media such as wolfram carbide or steel grinding media.

Milling requires both thermal stress and energy input, with longer processing potentially abrading grinding media and contaminating particles. Mechanical milling may be combined with reactive milling; here, chemical or physical reactions accompany the milling process.

As opposed to using chemical and physical production processes, using mills to crush particles yields powder products with relatively wide particle-size distribution ranges and does not allow full control over particle shape.

Gas Phase Technologies/Aerosol Processes

Aerosol processes have become one of the primary industrial-scale methods for producing nanomaterials in powder or film form.

Nanoparticles are created by producing a vapor of material using either chemical or physical means, then through homogenous nucleation they enter liquid or solid states for production.

Flame reactors produce nanoparticles by decomposing source molecules in flame at relatively high temperatures (1200-2200degC). Flame reactors are increasingly being utilized for industrial-scale production of soot, pigment-titanium dioxide particles and silicon dioxide particles.

Plasma reactors rely on plasma (ionized gas) as the source of energy to facilitate vaporization and initiate decomposition reactions.

Laser reactors utilize lasers to selectively heat gaseous source material using its absorption wavelength, and decompose it into desired products.

Hot wall reactors use vaporization and condensation processes for their source material vaporization and condensation processes, where source materials are heated before being vaporized under low pressure (around 1mbar). This removes any gas phase contamination in the hot zone while any particles created from rapid cooling are collected on filters for later collection by specialists. Traditionally used to produce nanoscale nickel and iron powders.

Chemical gas phase deposition (CGPD) is an efficient way of directly depositing nanoparticles from gas phase onto surfaces. Here, source material is vaporized under vacuum before condensing on heated surfaces through chemical reactions and then dedeposited from gas phase into solid final products.

is an established Nano Bi Powder supplier, boasting more than 12 years of expertise in chemical product research and development. If you are in search of premium Bismuth Nanoparticles Nano Bi Powder please feel free to get in touch and submit an inquiry.