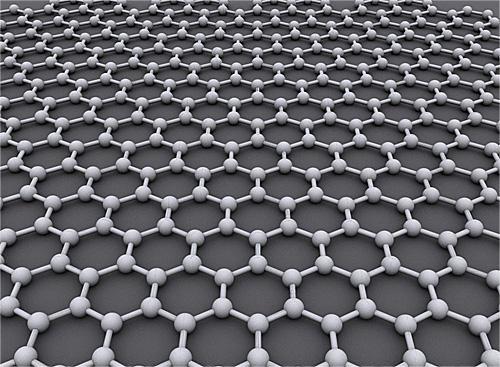

Graphene is a type of material that has revolutionized the field of materials science due to its exceptional mechanical, electrical, and thermal properties. It is also one of the most abundant and widely used materials in the world. However, turning solid graphite into graphene is not an easy task. Graphene synthesis requires specialized equipment, expertise, and precise control over the conditions. In this article, we will discuss the process of converting solid graphite into graphene.

(how do we turn solid graphite into graphene)

The process of converting solid graphite into graphene begins with the preparation of a graphite sample. The sample must be highly pure and free of impurities that could interfere with the graphene formation process. Once the sample is prepared, it must be subjected to high temperatures and pressures to break down the carbon atoms into monolayers or hexagonal structures. This process is known as exfoliation and it can be achieved using various techniques such as chemical vapor deposition (CVD), physical vapor deposition (PVD), and electrostatic Deposition.

One of the most common methods for exfoliating graphite is CVD, which stands for Carbon Dioxide Evaporation. This method involves exposing a graphite sample to high pressure and temperature to generate a gas of carbon dioxide, which reacts with the sample to form graphene sheets. Another method is PVD, which stands for Physical Vapor Deposition. This method involves exposing a graphite sample to a chemical precursor gas, which evaporates at high temperatures to form graphene sheets. Lastly, electrostatic Deposition involves applying electric fields to a graphite sample to generate graphene sheets.

After exfoliation, the graphene sheets need to be purified and separated from each other. This is done by rinsing the graphene sheets with water, which removes any impurities and ensures that the graphene sheets are free of defects and edges. Once the graphene sheets are clean, they can be processed further to obtain specific properties such as texture, size, and shape.

There are several factors that affect the quality and yield of graphene synthesis. These include the choice of graphite preparation technique, the pressure and temperature conditions, and the presence of impurities in the graphite sample. To improve the yield and quality of graphene synthesis, it is important to optimize these parameters. For example, using appropriate carbon source and pH levels can enhance the formation of graphene sheets. Additionally, controlling the reaction conditions can help to reduce the number of defects and edges in the graphene sheets.

(how do we turn solid graphite into graphene)

In conclusion, converting solid graphite into graphene is a complex and challenging process that requires specialized equipment, expertise, and precise control over the conditions. Despite the challenges involved, graphene synthesis has the potential to revolutionize the field of materials science and enable the development of new materials with unique properties. Further research and development efforts are needed to optimize the synthesis process and improve the yield and quality of graphene sheets.

Inquiry us