Title: How to Obtain Hydrophobic Graphene Dispersions

(how to obtain hydrophobic graphene dispersions)

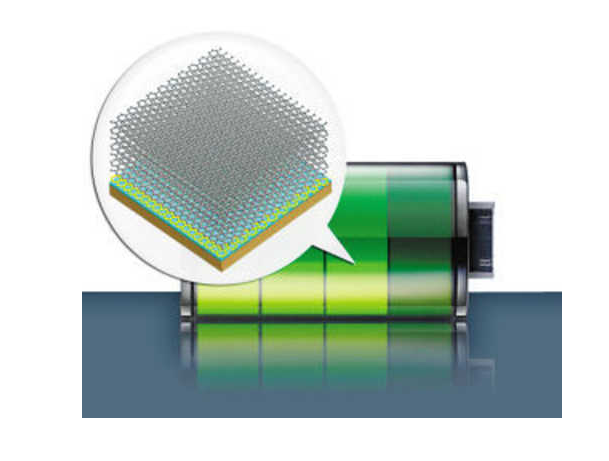

Graphene, a two-dimensional material consisting of carbon atoms arranged in a hexagonal lattice, has been attracting researchers and industry attention due to its unique properties. One such property is its hydrophobicity, which makes it useful for applications such as water-repellent coatings and biomedical surfaces. However, obtaining hydrophobic graphene dispersions can be challenging. This article aims to provide an overview of the process involved in obtaining hydrophobic graphene dispersions.

Materials needed:

1. Hydrophobic graphene: The starting material for obtaining hydrophobic graphene dispersions is hydrophobic graphene. This can be obtained through chemical vapor deposition (CVD) or physical vapor deposition (PVD).

2. Chemical solutions: Hydrophobic graphene requires specific chemical solutions that will dissolve the graphene and enable the formation of hydrophobic dispersion films.

3. Refractive index modifiers: To improve the hydrophobicity of the graphene dispersions, refractive index modifiers such as organic molecules or surfactants can be added.

4. Defects: Defects in the graphene such as vacancies, cracks, or interruptions in the hexagonal lattice can affect the hydrophobicity of the dispersion films.

Procedure:

1. Preparation of graphene samples: Clean and dry graphene samples using various cleaning methods. The preparation of graphene samples is critical to ensure consistent results in the subsequent steps.

2. Sample preparation: Prepare a series of graphene samples by varying the concentration of hydrogen gas used during CVD or PVD processes. The sample preparation method used depends on the desired purity of the graphene films.

3. Chemical solution preparation: Create a chemical solution containing the required components for the hydrophobic graphene dispersions. For example, if the hydrophobic graphene is obtained through CVD, the chemical solution may contain hydrophobic organic molecules or surfactants. If the hydrophobic graphene is obtained through PVD, the chemical solution may contain metal precursors or organic molecules.

4. Adsorption of hydrophobic solutions onto graphene: Add the selected chemical solutions into the graphene sample and stir them thoroughly. The adsorption of the hydrophobic solutions onto the graphene surface can be influenced by factors such as temperature, pressure, and humidity.

5. Deposition of hydrophobic graphene: After the chemical solution has been applied, use a suitable deposition technique to deposit the hydrophobic graphene onto the substrate. Deposition techniques such as gas-assisted plasma sputtering, chemical vapor deposition, or mechanical vapor transport (MVT) are commonly used for graphene synthesis.

6. Post-processing: The deposited hydrophobic graphene films need to be post-processed to remove any impurities or defects. This step typically involves chemical etching, etching using UV light, or photochemical reactions to remove surface contaminants.

7. Characterization of hydrophobic graphene dispersions: The obtained hydrophobic graphene dispersions should be characterized using various analytical techniques such as X-ray diffraction (XRD), scanning electron microscopy (SEM), transmission electron microscopy (TEM), and Fourier transform infrared spectroscopy (FTIR). These techniques help determine the quality, structure, and composition of the hydrophobic graphene dispersions.

Conclusion:

(how to obtain hydrophobic graphene dispersions)

Obtaining hydrophobic graphene dispersions is a complex process that requires careful planning and execution. By carefully selecting the appropriate materials, optimizing the sample preparation method, and employing appropriate deposition techniques, researchers can successfully obtain hydrophobic graphene dispersions with high quality and reproducibility. Understanding the underlying mechanisms of hydrophobic graphenedispersion formation is crucial for further applications in various fields, including electronics, biomedicine, and energy storage.

Inquiry us