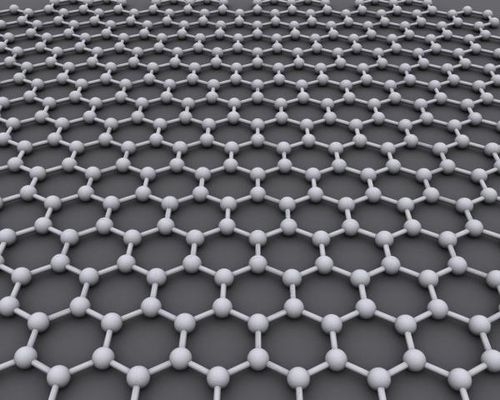

Graphene is an incredibly strong and conductive material that has revolutionized the field of nanotechnology. It is a two-dimensional material made up of carbon atoms arranged in a hexagonal lattice, which makes it unique in terms of its electrical conductivity, mechanical strength, and thermal stability. One way to coat metal with graphene is by using a chemical vapor deposition (CVD) method, which involves heating a metal surface to create a layer of graphene on top.

(how to coat metal with graphene)

The CVD process typically starts with a plasma, which is a gas containing ions, electrons, and other particles. This plasma is then ionized, creating positively charged particles called holes, and excited by high temperatures. These holes can react with the surface of the metal to form a new layer of graphene, while leaving behind a stable surface. The duration of the CVD process depends on various factors, including the temperature, pressure, and duration of the exposure.

Once the graphene layer is formed, it can be transferred to the metal surface using methods such as spin coating or electron beam erosion. The thickness of the graphene layer can be adjusted by adjusting the conditions of the CVD process. For example, the thickness of the graphene layer can be controlled by adjusting the duration of the exposure, while the temperature and pressure can affect the quality of the graphene layer.

There are several benefits of coating metal with graphene. Firstly, graphene has excellent electrical conductivity, which means that it can store and release electricity with very high efficiency. Secondly, graphene is highly resistant to corrosion and wear, making it a suitable material for use in applications such as sensors and actuators. Thirdly, graphene is highly transparent and can be used to improve the transparency of electronic devices.

One potential limitation of coating metal with graphene is that it may require specialized equipment and expertise to carry out the process. Additionally, the quality of the graphene layer produced may depend on the parameters of the CVD process, such as temperature, pressure, and duration of exposure. Therefore, further research is needed to optimize the process and improve the quality of the graphene layer.

(how to coat metal with graphene)

In conclusion, coating metal with graphene offers a number of advantages, including excellent electrical conductivity, resistance to corrosion and wear, and transparency. However, there are also challenges associated with the process, such as specialized equipment and expertise. As research in this area continues, we can expect to see further advancements in the development of new materials and technologies using graphene.

Inquiry us