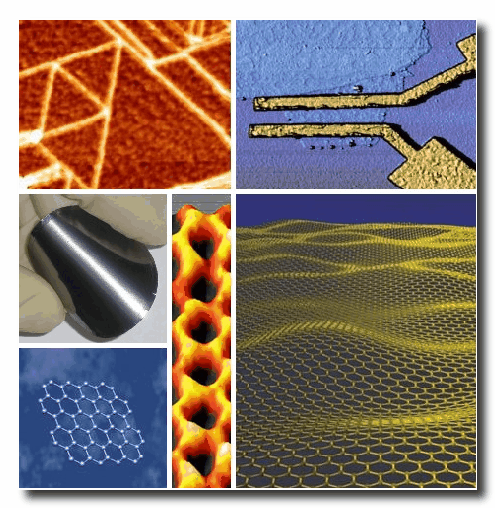

Graphene is a two-dimensional material consisting of a single layer of carbon atoms arranged in a hexagonal lattice. It has many unique properties that make it an ideal material for use in a variety of applications, including nanotechnology and cutting fluids.

(what makes graphene a suitable nanoadditive for cutting fluids used in micromachining)

One of the most significant advantages of graphene is its high surface area. Graphene is incredibly thin but extremely strong, which means that it can be used to create very large surfaces with very low roughness. This makes it ideal for use in applications where high precision and durability are required, such as in the manufacture of micro-mechanical components.

Another advantage of graphene is its electrical conductivity. Graphene is highly conductive due to the presence of thousands of carbon atoms packed closely together, which creates a conductive path through the material. This makes it ideal for use in applications where fast charge transfer is needed, such as in the production of electronic devices.

Additionally, graphene’s stability is another advantage over other materials. It is resistant to degradation under extreme temperatures and humidity, making it ideal for use in environments where exposure to heat or moisture is likely.

Graphene also has excellent mechanical strength and durability, making it ideal for use in applications where heavy loads and vibrations are present. Its unique structure also allows it to resist compression and bending, making it ideal for use in applications where flexibility is required.

Finally, graphene’s ease of fabrication is one of its greatest advantages. Graphene can be easily fabricated using various techniques, including chemical vapor deposition (CVD) and atomic layer deposition (ALD), which allows for rapid prototyping and mass production of high-quality graphene products.

(what makes graphene a suitable nanoadditive for cutting fluids used in micromachining)

In conclusion, graphene offers several advantages over other materials that make it an ideal material for use in cutting fluids used in micromachining. Its high surface area, electrical conductivity, stability, mechanical strength, and ease of fabrication make it a versatile material that can be used in a wide range of applications. As research into graphene continues to advance, we can expect to see even more innovative uses for this material in the future.

Inquiry us