Molding Graphene: A Comprehensive Guide

(how to mold graphene)

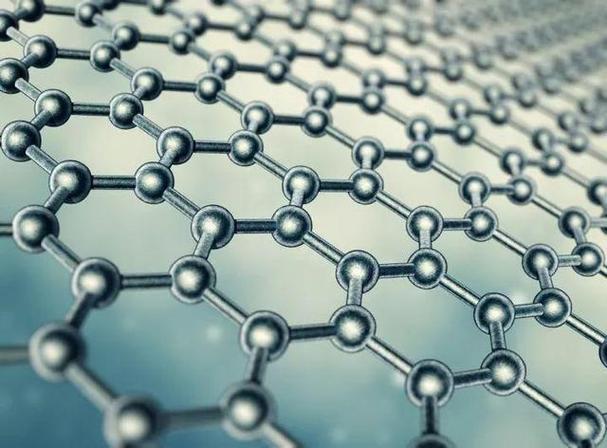

Graphene is an extremely strong and lightweight material, with properties that make it ideal for a wide range of applications. It has been hailed as a game-changer in materials science due to its unique properties, such as high electrical conductivity, thermal stability, and mechanical strength. However, like any new technology, creating graphenes requires specialized knowledge and equipment. In this article, we will explore how to mold graphene, from basic techniques to advanced techniques.

**Basic Techniques**

1. Equipment:

* A flat-bottomed container or mold

* An extruder or

* A temperature control system

* A clean and dry workspace

2. Material Preparation:

* Draw out a thin layer of graphene on a clean surface.

* Etch away any unwanted edges or impurities using a chemical etchant.

* Dry the graphene layer thoroughly before proceeding.

3. Molding Process:

* Place the graphene layer into the container or mold.

* Place the container on a heating platform or insert it into a vacuum chamber.

* Use the extruder or to shape the graphene layer into the desired form.

* Allow the mold to cool and solidify.

4. Post-Molding Processing:

* Cut out any excess graphene using a sharp tool.

* Test the properties of the finished product by measuring its electrical conductivity, thermal stability, and mechanical strength.

* Clean and store the product as needed.

**Advanced Techniques**

1. Digital Printing:

* Using a digital printer, print out a pattern onto the graphene sheet.

* Use the graphene sheet as a substrate and deposit color or other functional layers onto it.

* Print the final product using the same printing process as before.

2. Microimaging:

* Use a micro imaging device to create detailed images of the graphene sheet.

* This can be useful for studying the structure and composition of the graphene material at the molecular level.

* The resulting images can be used to optimize the production process or identify potential defects in the material.

3. Processing in the Lab:

* Use laboratory equipment to manipulate the graphene sheet and change its properties.

* For example, you could adjust the thickness of the graphene layer, change the chemistry used to etch the graphene, or alter the temperature at which the mold is heated.

(how to mold graphene)

In conclusion, molding graphene involves several steps, including preparing the graphene, shaping the graphene, post-molding processing, and more advanced techniques such as digital printing, microimaging, and processing in the lab. By following these steps, you can produce high-quality graphene materials with specific properties and characteristics tailored to your needs. Whether you’re working on a small prototype or large-scale production facility, mastering the art of graphene mold-making is crucial for unlocking its full potential.

Inquiry us