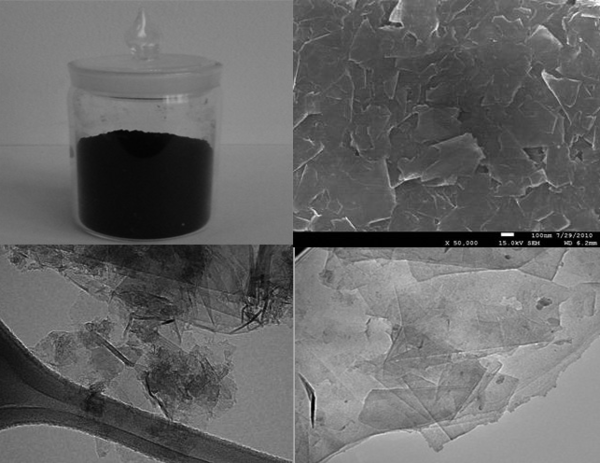

Graphene aerogel, also known as graphene oxide, is a new material that has gained significant attention in recent years due to its unique properties. The main advantage of graphene aerogel is its high surface area, which makes it ideal for applications such as gas adsorption, energy storage, and drug delivery.

(graphene aerogel How much does it cost to produce aerographene?)

However, the production process for graphene aerogel can be quite expensive. In order to produce large quantities of graphene aerogel, it requires the use of expensive equipment and chemicals. According to research published in the Journal of Materials Chemistry A, the cost of producing one gram of graphene aerogel can range from $12,000 to $30,000 depending on the method used.

The production process typically involves several steps, including:

1. Preparation of starting materials: The first step in the production process is to prepare the starting materials, which typically consist of graphene flakes or wafers. These flakes or wafers are then converted into powder using chemical methods such as chemical vapor deposition (CVD) or mechanical means such as sandblasting.

2. Preparation of catalysts: Catalysts are necessary to initiate the reaction between the graphene flakes or wafers and the reactants. Depending on the type of reactants, different catalysts may be used.

3. Solution of catalyst: Once the graphene flakes or wafers have been prepared and the catalysts have been added, the solution is prepared by mixing the flakes or wafers with an appropriate solvent such as methanol or ethanol.

4. Solution aging: The solution is then aged for a certain period of time to allow the graphene flakes or wafers to fully penetrate the solution. This can be achieved through various methods such as temperature control or exposure to UV light.

5. Solvent evaporation: After the solution has aged, it is removed from the substrate using solvent evaporation techniques. This is done to obtain the desired amount of graphene aerogel.

The production process for graphene aerogel can be complex and expensive, making it difficult for many companies to mass-produce large quantities of the material. As a result, the cost of graphene aerogel can vary widely depending on the size and quantity of the product being produced. However, advancements in technology and lower production costs are expected to make graphene aerogel more accessible to consumers in the future.

(graphene aerogel How much does it cost to produce aerographene?)

In conclusion, while the production process for graphene aerogel can be expensive, the potential benefits of the material make it worth considering for various applications. With ongoing technological advancements and decreasing production costs, graphene aerogel is likely to become a more common and valuable material in the near future.

Inquiry us