Title: How to Infuse Plastic and Graphene: A Comprehensive Guide

(how to infuse plastic and graphene)

Plastic, a common material used in various products, is known for its durability and versatility. However, there is a growing concern about the environmental impact of plastic production and disposal. On the other hand, graphene has shown exceptional properties that could revolutionize various industries, including electronics, medicine, and energy storage. Here’s how to infuse plastic and graphene into each other.

## Introduction

Plastic is a versatile and durable material that is widely used in manufacturing a variety of products. It is made from petrochemicals, such as and natural gas, which are abundant sources of energy. Despite its usefulness, plastic pollution is becoming a major environmental problem, and there is an increasing demand for alternative materials that can replace it.

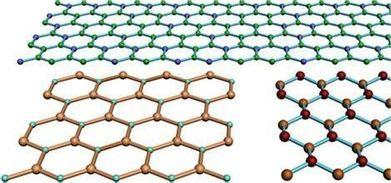

Graphene, on the other hand, is a two-dimensional material composed of carbon atoms arranged in a hexagonal lattice structure. It has remarkable electrical and thermal conductivity, making it ideal for use in electronic devices, batteries, and energy storage systems. However, graphene is also expensive and difficult to produce on a large scale.

Infusing plastic and graphene together presents a unique opportunity to create a new type of composite material that combines the benefits of both materials. In this article, we will discuss how to infuse plastic and graphene together and explore some of their potential applications.

## Infusing Plastic and Graphene

The process of infusing plastic and graphene involves melting the plastic and mixing it with the graphene powder or sheet. The resulting mixture is then extruded through a die, allowing it to cool and solidify. This method of processing produces a composite material that contains both plastics and graphene.

### Melting Plastic and Mixing with Graphene

To melt plastic and mix it with graphene, you’ll need to have access to the necessary equipment and supplies. You’ll also need to follow proper safety precautions, such as wearing protective gear and using a heated surface when working with heat.

To melt plastic, you’ll typically use an electric heating element or a furnace. To mix with graphene, you may want to add small amounts of graphene powder or sheet to the plastic solution. Alternatively, you can purchase pre-mixed graphene sheets that have been chemically treated to enhance their functionality.

Once you have melted the plastic and mixed it with graphene, you can then proceed to extrude the mixture through a die. This step involves cooling the mixture to room temperature, ensuring that it is free of air bubbles and other impurities. Once the mixture is cool enough, you can place it on a baking sheet and bake it at a high temperature until it hardens.

### Benefits of Infusing Plastic and Graphene

Infusing plastic and graphene together offers several potential benefits over traditional plastic products. For example:

1. **Low Cost:** By replacing one type of plastic with another, you can reduce your environmental impact while also potentially lowering your manufacturing costs.

2. **Durability:** Graphene is known for its exceptional strength and durability, making it an excellent material for creating products that can withstand daily wear and tear.

3. **Energy Efficiency:** With its superior insulation properties, graphene can help improve the energy efficiency of various devices, such as.

4. **Recyclability:** By combining plastic and graphene, you can create a more sustainable product that can be easily recycled at the end of its life.

## Applications of Infused Plastic and Graphene

There are many potential applications for infused plastic and graphene. Some examples include:

1. **Electronic Devices:** Graphene is highly conductive, making it an ideal material for creating electronic components such as memory chips and sensors.

2. **Batteries:** Plastic provides a strong and durable battery case, making it an ideal choice for electronic devices that require long-lasting power.

3. **Energy Storage:** By integrating graphene into various energy storage technologies, you can improve the performance and efficiency of these systems.

4. **Electronics Manufacturing:** By incorporating plastic and graphene into the production process, manufacturers can create more environmentally friendly and cost-effective products.

## Conclusion

(how to infuse plastic and graphene)

Infusing plastic and graphene together presents a promising new direction for the development of eco-friendly and durable products. While there are still challenges to overcome, such as the high cost and difficulty of producing graphene on a large scale, the potential benefits of using these materials in combination make it a compelling option for manufacturers looking to reduce their environmental impact while improving the performance of their products. As technology continues to advance, we can expect to see even more innovative uses of infused plastic and graphene in the future.