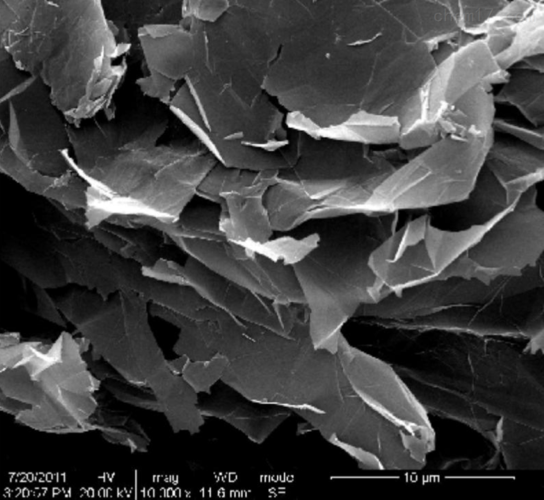

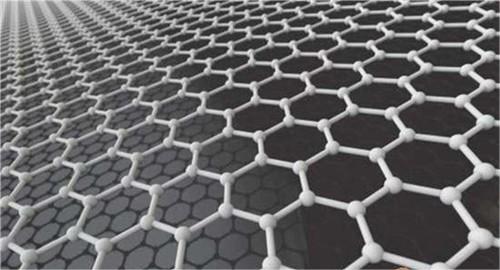

Graphene is a single layer of carbon atoms arranged in a hexagonal lattice, making it an incredibly strong and flexible material. However, like all materials, graphene can also be contaminated by impurities or defects that could affect its performance.

(graphene annealing: how clean can it be?)

One way to ensure that graphene is free from these contaminants is through the process of graphene Annealing, which involves heating the graphene samples to very high temperatures in order to remove any remaining defects or impurities. While this process can help improve the purity of graphene, it can also lead to some unexpected consequences.

One potential issue with graphene Annealing is that it can cause damage to the graphene atoms. When graphene is heated to extremely high temperatures, the atoms can become more reactive and prone to chemical reactions, which can lead to changes in their structure or behavior. This can make it difficult for the graphene to function properly as intended, and can potentially affect its strength or other properties.

Another concern about graphene Annealing is that it may not always result in perfect results. There is still some uncertainty about how well the process will work, and there may be variations in the final product depending on a variety of factors. For example, the type of graphene being used, as well as the conditions under which it is heated, can all impact the quality of the resulting graphene.

Despite these challenges, however, graphene Annealing remains a promising approach for improving the purity and functionality of graphene. By carefully controlling the temperature and duration of the annealing process, researchers hope to be able to produce graphene with improved purity and fewer defects. This could have important implications for a wide range of applications, including electronics, energy storage, and biomedical devices.

(graphene annealing: how clean can it be?)

In conclusion, while graphene Annealing can help improve the purity and functionality of graphene, it does pose some potential challenges as well. As researchers continue to explore this technology, it will be important to carefully consider the effects of Annealing on the graphene and to develop methods for mitigating these risks. With continued research and development, we may one day see even more precise and efficient ways to produce graphene that meet the needs of a wide range of industries.

Inquiry us