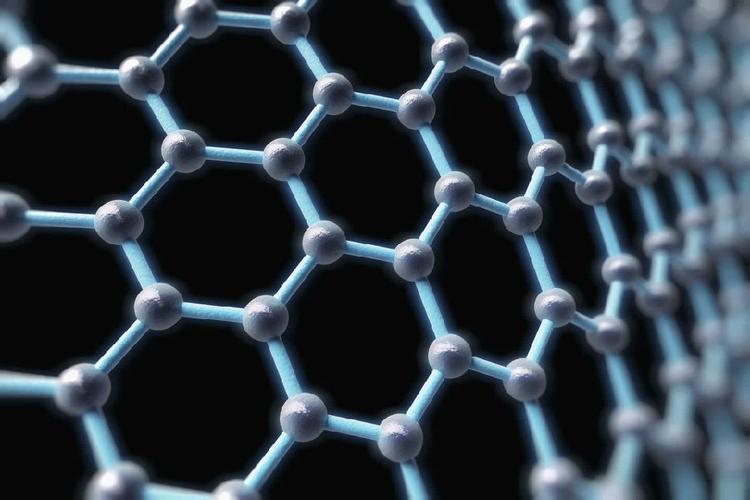

Graphene, a two-dimensional material consisting of carbon atoms arranged in a hexagonal lattice structure, has gained significant attention in recent years due to its unique properties. Despite its high electrical conductivity and mechanical strength, graphene is still relatively expensive to produce on a large scale.

(how expensive is graphene?)

One of the main factors contributing to the cost of graphene is the cost of raw materials. Graphene is typically produced using a process called chemical vapor deposition (CVD), which involves heating a gas containing carbon precursors in a vacuum to create graphene. The cost of CVD equipment and raw materials such as carbon powder and metal catalysts can be quite high.

Another factor that affects the cost of graphene is the complexity of the manufacturing process. Graphene production typically requires specialized equipment and expertise, including high-performance computing power and advanced robotics. These costs add up significantly to the overall cost of graphene products.

The cost of graphene can also vary depending on the intended application of the product. For example, graphene can be used for applications such as electronics, energy storage, and medicine, each with their own set of requirements and challenges. The higher the demand for graphene, the more expensive it becomes to produce and market it.

In addition to the cost of raw materials and manufacturing processes, the high demand for graphene also drives up prices. As demand for graphene increases, so do the costs associated with producing it. This phenomenon is known as supply chain inflation, and it can lead to higher prices for consumers.

(how expensive is graphene?)

Overall, while graphene has many potential benefits, its cost remains a significant challenge. While advances in technology and economies of scale may eventually reduce the cost of graphene, it will likely remain a premium product for a long time to come.

Inquiry us