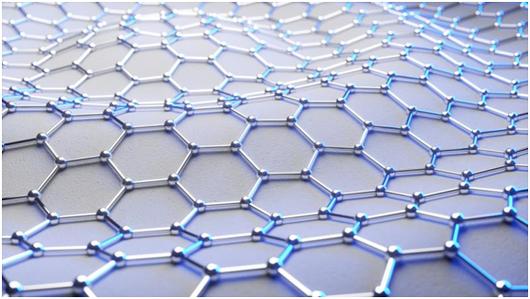

Graphene, a two-dimensional material made from carbon atoms arranged in a hexagonal lattice structure, has gained widespread attention due to its unique properties and potential applications in various fields. Graphene can be produced through several methods, including chemical vapor deposition (CVD), mechanical exfoliation, and chemical reduction.

(how graphene is manufactured)

One of the most common methods for manufacturing graphene is through CVD, which involves exposing a substrate to high temperatures and pressures under a vacuum to create a single layer of graphene. The process typically starts with an oxidizing gas or plasma and reacts with a metal oxide film on the substrate, depositing carbon atoms onto the surface at a rate controlled by temperature and pressure. The resulting graphene sheet has a very high electron mobility and a strong magnetic moment.

Another method for producing graphene is mechanical exfoliation, which involves using physical force to remove layers of graphene from a solid material such as. This method typically involves applying stress to the material and then of the graphene layer that is removed. The resulting layer is then used to produce a new graphene sheet.

Finally, chemical reduction can also be used to produce graphene. In this process, a molecule such as methane is reduced to form a new graphene sheet. The reaction typically involves heating a mixture of methane and an acid, such as hydrogen peroxide, and then allowing it to react until the product is formed.

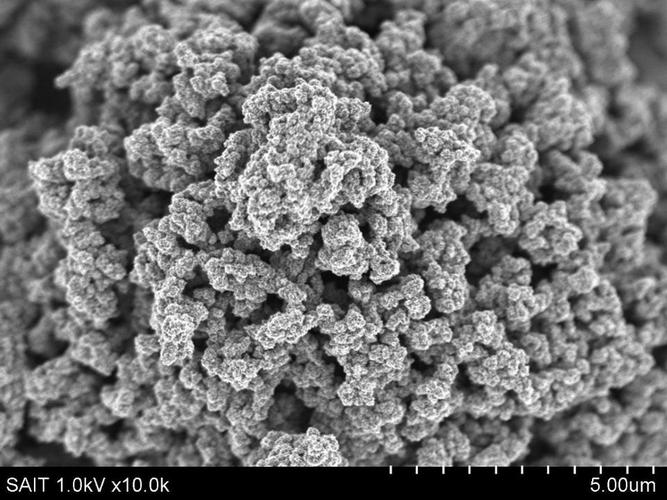

Despite these methods, there are still some challenges associated with manufacturing graphene. One of the biggest concerns is scalability, as increasing the number of layers on a single graphene sheet becomes increasingly difficult. Another challenge is controlling the quality of the graphene, as impurities and defects can affect its electrical and thermal properties.

Despite these challenges, graphene has shown great promise in a variety of fields. It is being used as a conductive material in electronic devices, as a material in flexible electronics, and as a sensing material in medical imaging. It is also being studied for potential use in energy storage and transportation systems.

(how graphene is manufactured)

In conclusion, graphene can be manufactured through several methods, including CVD, mechanical exfoliation, and chemical reduction. While there are still challenges associated with scaling up production, the potential benefits of graphene make it a promising material with significant potential applications in various fields.

Inquiry us