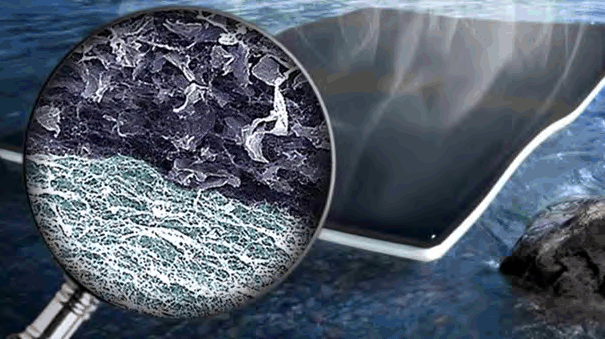

Graphene is a highly conductive material that has gained a lot of attention in recent years due to its unique properties, including high electrical conductivity and mechanical strength. Graphene filters have been proposed as a potential replacement for traditional oil and gas filters due to their ability to remove small particles from liquids more effectively than other materials.

(how is a graphene filter made)

One way to make a graphene filter is to start by depositing graphene sheets onto a substrate such as paper or plastic. The graphene sheets can be synthesized using various methods, including chemical vapor deposition (CVD) or electrochemical reduction. Once the graphene sheets are prepared, they can be cleaned and used as the filter media.

The quality of the graphene filter depends on several factors, including the thickness and composition of the graphene sheets, the substrate on which the graphene is deposited, and the method used to clean and refine the filter. Thicker and more homogeneous graphene layers will result in better filtering performance, but they may also require more energy and processing time.

There are also various modifications that can be made to the graphene filter to improve its performance. For example, researchers have proposed adding impurities or coatings to the graphene layer to enhance its adsorption capacity. They have also developed new fabrication techniques for producing larger, more uniform graphene sheets, which could lead to even greater improvements in filtering performance.

Another important factor to consider when making a graphene filter is the cost of production. Graphene is a relatively expensive material to produce, so it is important to ensure that the filtered liquid is produced efficiently and economically.

(how is a graphene filter made)

In conclusion, making a graphene filter involves starting by preparing graphene sheets on a substrate, cleaning and refining them, and adjusting the thickness and composition to achieve the desired filtering performance. There are many ways to modify the graphene filter to improve its performance, but careful consideration of factors such as cost and filtration efficiency is crucial. With continued research and development, graphene filters have the potential to revolutionize the industry and provide a more efficient and sustainable solution to waste water treatment and pollution control.

Inquiry us