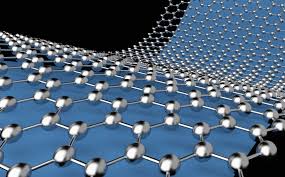

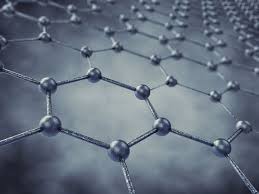

Graphene, a material with incredible properties, has become a popular topic in recent years due to its potential applications in various fields such as electronics, energy storage, and medicine. Graphene is a two-dimensional atomic network consisting of carbon atoms arranged in a hexagonal lattice structure.

(how is graphene made?)

The process of making graphene involves several steps, including growing it on a substrate, removing impurities, and refining the quality of the final product. Here’s a brief overview of each step:

1. Growing graphene on a substrate: Graphene can be grown on various substrates such as、、. One common method for growing graphene is through chemical vapor deposition (CVD), where high-temperature gas is vaporized and deposited onto a substrate using an electric field. CVD results in graphene that is highly ordered and free of defects.

2. Removing impurities: Once graphene has been grown on a substrate, impurities can accumulate at the surface. These impurities can cause instability in the graphene layer and reduce its overall performance. To remove these impurities, techniques such as chemical etching or ionizing them with UV light are used.

3. Refining the quality of the final product: After removing impurities, the quality of the graphene layer needs to be further refined. This involves using high-quality materials and processes such as physical vapor deposition (PVD) or chemical vapor deposition (CVD). PVD uses a plasma to deposit thin layers of graphene onto a substrate, while CVD uses high-temperature gases to vaporize and deposit graphene.

(how is graphene made?)

Overall, making graphene involves a series of complex and carefully controlled processes that result in a material with exceptional properties. While there is still much research being done to improve the synthesis and processing of graphene, it holds great promise for many applications in the future.

Inquiry us