Graphene oxide (GO) is a new material that has been shown to have a wide range of potential applications in fields such as electronics, energy storage, and medicine. However, the process of making GO can be complex and requires careful control over a variety of factors.

(how is graphene oxide made)

The first step in making GO is to prepare the carbon precursors used in the synthesis. These precursors typically consist of hydrocarbons such as methane, ethane, or propylene, which are combined together under high pressure and temperature. The resulting gas contains carbon atoms bonded together in a three-dimensional network structure known as a “carbon nanotube.”

Once the carbon precursors have been prepared, they must be dissolved in water to form a solution. This solution will contain one molecule of carbon nanotube per liter. The carbon nanotubes will then be extracted from the solution using a solvent such as methanol or ethanol.

The resulting solution is then converted into a liquid through a series of chemical reactions, including the reaction between the hydrocarbons and various metal salts to produce the desired grapheme oxide.

There are several factors that affect the yield and purity of graphene oxide. For example, the choice of precursor and solvent can greatly impact the size and shape of the carbon nanotubes produced. Additionally, the temperature and pressure at which the synthesis takes place can also affect the properties of the resulting material.

One of the most promising applications of graphene oxide is its use as an electronic material. Graphene oxide has a unique electronic band structure, which makes it ideal for use as a conductor or insulator. It is also highly transparent and conductive under certain conditions, which makes it useful for applications such as solar cells and wearable electronics.

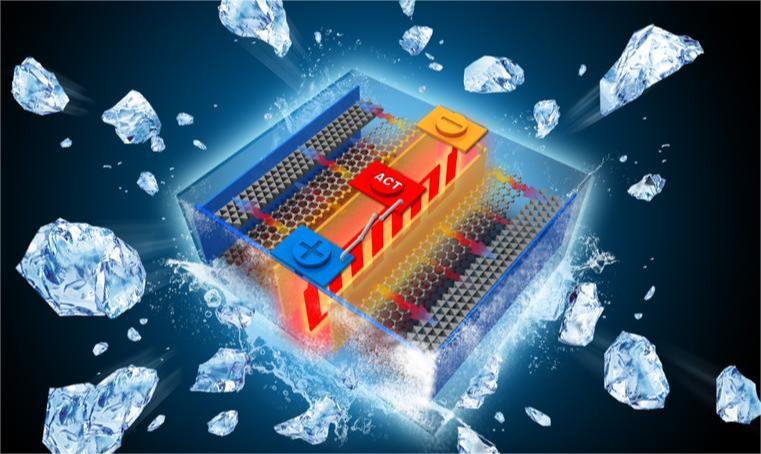

Another potential application of graphene oxide is its use as an energy storage material. Graphene oxide can store a large amount of energy due to its excellent electrical conductivity. This makes it a promising material for use in batteries and other power storage devices.

Finally, graphene oxide has the potential to be used as a drug delivery system. Graphene oxide can be used to encapsulate drugs within its surface, which can help to increase their efficacy by reducing their exposure to stomach acid and other digestive enzymes.

(how is graphene oxide made)

In conclusion, the process of making graphene oxide involves the preparation of carbon precursors and the conversion of these precursors into a liquid through chemical reactions. There are several factors that can affect the yield and purity of the resulting material, and researchers are working to optimize these processes in order to improve the properties of graphene oxide for use in a variety of applications.

Inquiry us