Graphene, a two-dimensional material with unique properties such as high strength, flexibility, and conductivity, has been attracting widespread attention due to its potential applications in various fields such as electronics, energy storage, and aerospace engineering. However, before graphene can be used for commercial applications, it must undergo processing steps that transform it into the desired form. This process typically involves mechanical exfoliation, chemical functionalization, and characterization techniques.

(how is graphene processed from raw material)

Mechanical exfoliation is the first step in the production process of graphene. It involves removing flakes of graphene from bulk materials by using physical forces such as heat or pressure. This step is crucial because it removes any impurities or contaminants that may have accumulated during the growth process. The frequency and force of the exfoliation process determine the degree of graphene purity achieved.

Chemical functionalization is the second step in the production process of graphene. This step involves introducing functional groups onto graphene to modify its electrical, thermal, and mechanical properties. Common functionalization methods include chemical vapor deposition (CVD), chemical reduction, and chemical oxidation. CVD involves exposing graphene to a reactive gas such as carbon monoxide, while CVD involves exposing graphene to a reactive gas such as hydrogen. Chemical reduction involves treating graphene with reducing agents such as hydrogen or carbon monoxide, while chemical oxidation involves treating graphene with oxidizing agents such as oxygen or sulfur.

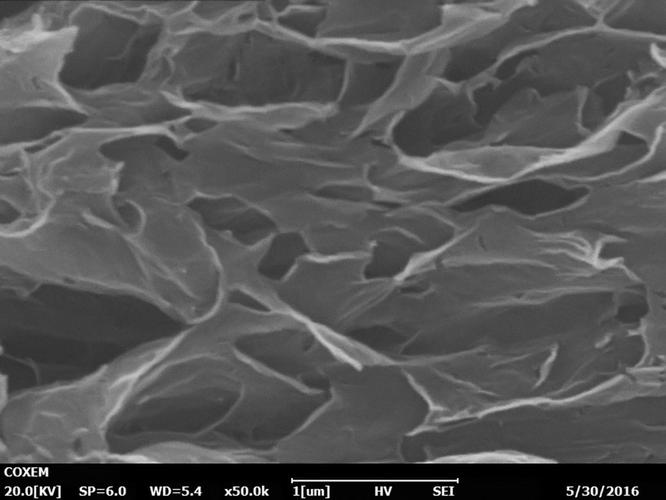

Characterization techniques are used to determine the quality and purity of graphene produced through these processes. These techniques include X-ray diffraction (XRD), scanning electron microscopy (SEM), transmission electron microscopy (TEM), and chemical analysis. XRD is used to identify the crystal structure and size of graphene samples, SEM is used to observe the surface roughness and texture of graphene samples, TEM is used to investigate the structural and topological features of graphene samples, and chemical analysis is used to determine the composition and purity of graphene samples.

(how is graphene processed from raw material)

In conclusion, graphene production from raw material involves several steps that transform it into the desired form. Mechanical exfoliation is the first step in the process, followed by chemical functionalization, and finally, characterization techniques are used to determine the quality and purity of graphene produced. Despite these steps, there is still much research that needs to be done to fully understand the potential of graphene and develop new ways of producing and utilizing this versatile material.

Inquiry us