Graphene is a unique and versatile material that has revolutionized the electronics industry due to its exceptional properties, such as high electrical conductivity, low reactivity, and lightweight. It is also extremely strong and durable, making it ideal for use in electronic circuits. Graphene-based interconnects have been widely explored as a potential alternative to traditional interconnects in various applications, including automotive, aerospace, and energy storage systems.

(how to create graphene based interconnects)

One of the key benefits of graphene-based interconnects is their high efficiency. Traditional interconnects can suffer from signal loss or distortion due to factors such as electromagnetic interference (EMI) and capacitance. However, graphene has a highly conductive surface area and can effectively carryover. The properties of graphene enable it to carry electrical signals without any loss or distortions.

Another advantage of graphene-based interconnects is their stability. Graphene is an extremely stable material, meaning that it does not easily decompose over time. This makes it ideal for use in long-lasting electronic devices.

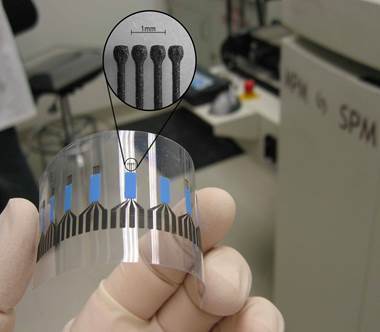

To create graphene-based interconnects, you will need to first prepare the graphene samples by exposing them to extreme temperatures and pressures until they form a two-dimensional film. Once the graphene films have formed, you can then use them as a substrate for your interconnects.

There are several methods for creating graphene-based interconnects, including chemical vapor deposition (CVD), physical vapor deposition (PVD), and plasma-enhanced chemical vapor deposition (PECVD). Each method has its own advantages and disadvantages, so it’s important to choose the right method for your specific application.

Chemical vapor deposition (CVD) involves passing carbon dioxide gas through a substrate to create a thin layer of graphene on top of it. PVD involves using high-powered laser beams to vaporize a film of carbon dioxide and create a graphene layer on top of it. Plasma-enhanced chemical vapor deposition (PECVD) uses plasma to create a graphene layer on top of a substrate.

When creating graphene-based interconnects, it’s important to consider factors such as substrate quality, laser power, and deposition conditions. A well-crafted substrate is essential for ensuring a successful graphene-based interconnect.

(how to create graphene based interconnects)

In conclusion, graphene-based interconnects offer a wide range of advantages over traditional interconnects, including high efficiency, stability, and suitability for use in long-lasting electronic devices. To create graphene-based interconnects, you will need to carefully prepare graphene samples and select the appropriate method for your specific application. With careful consideration of substrate quality, laser power, and deposition conditions, you can create graphene-based interconnects that are efficient, stable, and suitable for use in a variety of applications.

Inquiry us