Title: How to Deposit Graphene Oxide: A Comprehensive Guide

(how to deposit graphene oxide)

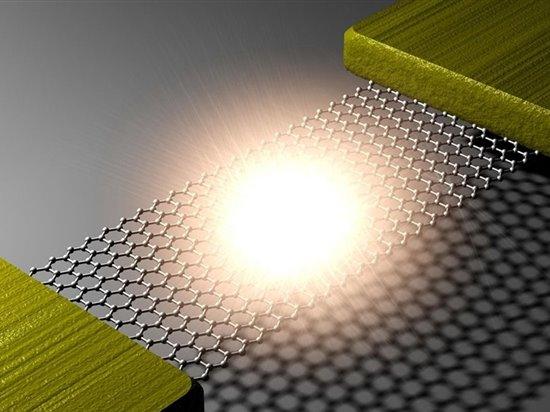

Graphene oxide (GO) is a two-dimensional material that has been attracting increasing attention in the field of materials science due to its unique properties, such as high electrical conductivity and exceptional mechanical strength. However, many people may not know how to deposit GO without specialized equipment or knowledge. In this article, we will provide a comprehensive guide on how to deposit GO using various methods.

Materials Required:

– Graphene oxides (GO)

– Molecular-beam epitaxy (MBE)

– PBE (Plane-Bonded Electron Configuration)

– deposition chemicals (e.g., metal nanocrystals)

Method 1: Method 1: Method 1 is the most common method for depositing GO. This method involves preparing a film of GO on a substrate using MBE or PBE technique. The substrate can be any material that supports the growth of GO films, such as silicon wafer, carbon fiber composite, or metal oxide.

The first step is to prepare the substrates by depositing reactive oxides onto them using the MBE method. This involves exposing the substrate to ultraviolet light for a specific period, followed by evaporation of the reactive oxides. Once the substrate is dry, it can be sliced into thin layers using sharp tools like files or glass. The resulting layer of GO is then used as a template to create subsequent layers of GO films.

Alternatively, the PBE method can be used to deposit GO films on other substrates. In this method, the substrate is first treated with UV light to activate the reactive oxygen species, which are then used to form the GO layers. The resulting layer of GO films can be dried and sliced into thin layers as described above.

Method 2: Method 2: Method 2 is similar to Method 1, but it uses an etched pattern instead of a template to create GO layers. The etched pattern can be designed using computer-aided design (CAD) software. Once the pattern is designed, it is etched onto the substrate using an etchant, such as potassium hydroxide (KOH). After the pattern is etched, the substrate can be sliced into thin layers using sharp tools like files or glass. The resulting layer of GO is then used as a template to create subsequent layers of GO films.

Method 3: Method 3: Method 3 involves using a combination of chemical and physical vapor deposition (CVD) techniques to deposit GO films on substrates. CVD is a process where a plasma is generated and used to vaporize reactants such as oxides, adsorbents, or precursors. The reactants are introduced into the plasma and allowed to grow at high temperatures until they form GO layers. Once the GO layers are formed, they can be sliced into thin layers using sharp tools like files or glass. The resulting layer of GO is then used as a template to create subsequent layers of GO films.

(how to deposit graphene oxide)

Conclusion: Conclusion: In conclusion, depositing graphene oxide (GO) using various methods requires careful preparation of substrates, proper treatment of reactive oxides, and precise control of parameters such as temperature, pressure, and time. By following these guidelines, you can successfully deposit GO films on various substrates, and even customize your GO synthesis according to your needs. As the technology continues to advance, we can expect more efficient and versatile methods for GO deposition, leading to even more exciting applications in fields such as electronics, energy storage, and nanotechnology.

Inquiry us