Title: How to Make a Sprayer for Deposition of Graphene

(how to make a sprayer for deposition of graphene)

Introduction:

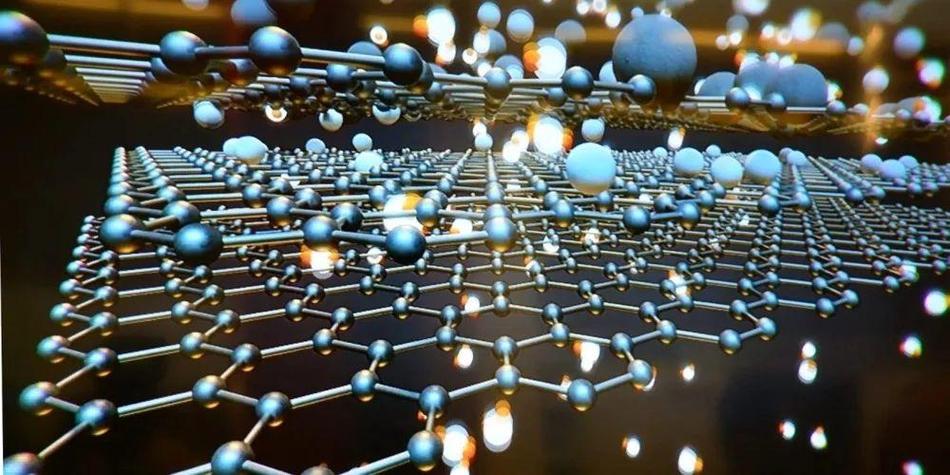

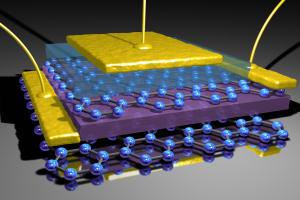

Graphene, the world’s strongest and most conductive material, has emerged as a promising candidate for a variety of applications in electronics, energy storage, and more. To make a spray system for deposition of graphene, you will need several components, including a spray head, a liquid carrier, a pump, and a drying system.

Components:

* Spray head: The spray head is responsible for creating the droplets of graphene that can be deposited onto a substrate. There are many different types of spray heads available, each with its own unique features and capabilities.

* Liquid carrier: The liquid carrier is used to carry the graphene droplets to the deposition site. Common choices include acetone or methanol.

* Pump: The pump is responsible for delivering the liquid carrier to the spray head and for mixing it with the graphene droplets before they are deposited.

* Drying system: The drying system removes any excess moisture from the graphene droplets after they have been deposited.

Designing the System:

To design the system, you will need to consider several factors such as the type of graphene being deposited, the substrate being used, and the desired deposition rate. You will also need to choose the appropriate spray head based on the properties of the graphene and the substrate.

Once the design is complete, you can begin building the system. This may involve assembling all the components and connecting them together using appropriate connections. It is important to ensure that the system is functioning properly before attempting to use it.

Testing and Optimization:

After the system has been built, it is important to test it thoroughly to ensure that it is working correctly. This may involve conducting experiments with different parameters such as the flow rate, concentration, and pressure of the liquid carrier to determine the optimal conditions for the deposition process.

It is also important to optimize the system by adjusting the properties of the graphene and the substrate, as well as the flow rate and pressure of the liquid carrier. This may involve conducting further experiments to find the best combination of these parameters for the specific application.

Conclusion:

(how to make a sprayer for deposition of graphene)

Making a spray system for deposition of graphene requires careful planning and design. With the right components and testing procedures, however, you can create a highly efficient and effective system that can help bring the benefits of graphene to a wide range of industries.

Inquiry us