Graphene is a unique material that has the potential to revolutionize many industries, including aerospace and automotive. It is composed of carbon atoms arranged in a hexagonal lattice structure, making it incredibly strong and lightweight. Graphene aerofoams (GAFs) can be made using a variety of methods, but one of the most promising is the use of high-performance polymers such as polyethylene terephthalate (PET). Here’s how you can make GAFs using PET.

(how to make graphene aerofoam)

## Setting Up the Machine

The first step in making GAFs using PET is setting up the equipment. This will involve mixing different components together in a specific ratio, which can vary depending on the desired properties of the GAF. The machine used for this process will typically include a pump, stirrer, thermometer, and weigher.

Once all of the necessary components have been mixed, they need to be shaped into the desired form. This can be done using various techniques, including injection molding or extrusion. Injection molding involves injecting a molten polymer mixture into a mold, while extrusion involves forcing a liquid plastic through a die to create a flexible film.

## Choosing the Right Polymer

The type of polymer used in the GAFs manufacturing process will depend on its specific properties. For example, if the goal is to create a strong and durable foam, then high-performance polymers like PET may be a good choice. If the goal is to create a lightweight and breathable material, then lightweight and breathable polymers like polyurethane may be a better option.

It’s important to choose the right polymer for your particular application, so it’s a good idea to do some research and consult with experts before making a decision. There are many resources available online and at industry conferences that can provide information on the different types of polymers and their properties.

## Processing the Mixture

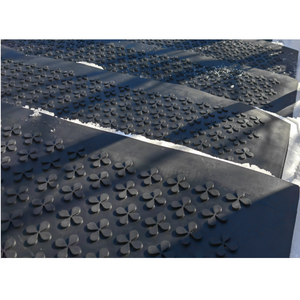

Once the polymer has been chosen, it needs to be processed to ensure that it is ready for use in the GAF. This can involve melting the polymer at a specific temperature and pressure, shaping it into the desired form, and adding reinforcing materials like fibers or nanoparticles.

The processing method used will depend on the specific requirements of the GAF. For example, if the GAF needs to be shipped quickly, then it may be more efficient to melt the polymer and mix it into a pre-formed shape. If the GAF needs to be made with higher strength, then it may require additional processing steps to strengthen the matrix.

## Testing the Product

Once the GAF has been processed, it needs to be tested to ensure that it meets the desired specifications. This can involve measuring its strength, density, and other properties, as well as testing it under load to ensure that it performs as expected.

There are several methods for testing GAFs, including tensile testing, impact testing, and fatigue testing. Tensile testing measures the material’s ability to withstand tension over a certain distance, while impact testing measures the material’s ability to absorb and distribute stress during impact. Fatigue testing measures the material’s ability to maintain its performance over long periods of time.

## Packaging the Product

Once the GAF has been tested and deemed suitable, it needs to be packaged to ensure that it arrives safely and effectively at its destination. This can involve wrapping the product in protective materials such as shrink wrap or foam, as well as labeling it with relevant information such as its composition and intended use.

(how to make graphene aerofoam)

In conclusion, making GAFs using PET requires careful planning and attention to detail. By following these steps, you can create high-performance polymers that meet the specific requirements of your application and deliver exceptional results. With advances in technology and materials science, the possibilities for using GAFs are virtually limitless, and we’re likely to see even more innovative uses in the future.

Inquiry us