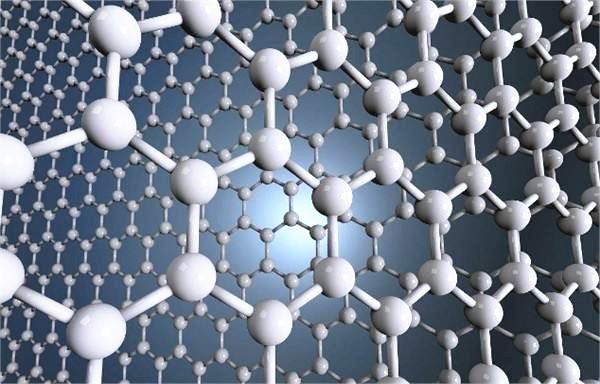

Graphene is a two-dimensional material made from carbon atoms arranged in a honeycomb lattice structure. It has numerous applications, including electronics, energy storage, and biotechnology. However, making graphene at home can be challenging due to its high cost and required specialized equipment.

(how to make graphene coated sand)

One way to create graphene at home is through chemical vapor deposition (CVD), which involves heating a carbon source in the presence of a reactive gas to produce graphene. The process typically requires the use of a vacuum chamber and a high temperature oven.

To prepare the graphene for CVD, you will need to obtain pure graphene from an industrial supplier or purchase it as a byproduct of other materials such as graphite or bamboo fibers. Once you have the graphene, you will need to remove any impurities using a washing process.

Once you have the graphene, you can apply it to a substrate such as silicon or aluminum oxide using a process called plasma etching. This process uses ionized gas to create small holes on the surface of the substrate, which allows the graphene to adhere to the surface.

The final step in making graphene coated sand is to cool the substrate down to room temperature before applying the graphene layer. This allows the graphene to adhere more strongly to the substrate and results in a harder and more durable sand.

(how to make graphene coated sand)

Overall, making graphene coated sand at home can be a fun and rewarding experience. With the right equipment and materials, you can produce graphene that is suitable for various applications, such as creating electronic circuits or creating eco-friendly building materials.

Inquiry us