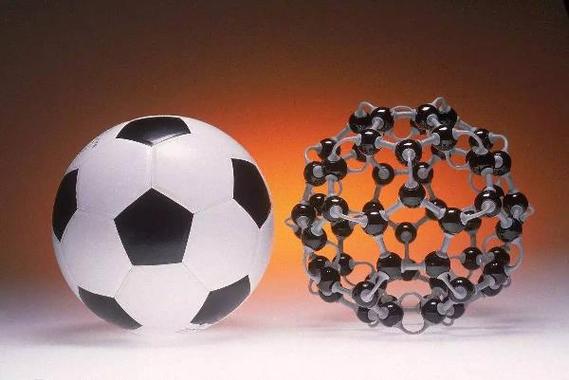

Graphene is a two-dimensional material consisting of carbon atoms arranged in a hexagonal lattice structure. Its unique properties, including high strength, electrical conductivity, and thermal stability, have made it an active area of research in materials science.

(how to make graphene nanoribbons)

There are several methods for making graphene nanoribbons, but one of the most popular approaches involves chemical vapor deposition (CVD). CVD involves exposing a thin film of metal or semiconductor on a substrate to a plasma generated by a gas such as nitrogen or argon. This process can produce graphene nanoribbons with length up to tens of micrometers.

Another method for making graphene nanoribbons is mechanical exfoliation. This involves using a mechanical force to break apart a graphene sheet into smaller pieces, which can then be separated and processed further.

In addition to these traditional methods, there are also some recent advances in techniques that enable the creation of graphene nanoribbons with even longer lengths. One example is chemical vapor transport (CVT), which involves using a high-temperature gas to control the flow of carbon monoxide through a graphene layer. This process can create ribbons with lengths up to tens of centimeters.

Another innovative approach to creating graphene nanoribbons is focused ion beam milling (FIM), which involves firing ions at a target graphene layer using electron energy transfer. The ions can cause a temporary disruption of the lattice structure, allowing for the formation of smaller ribbons.

(how to make graphene nanoribbons)

Overall, the process of making graphene nanoribbons involves a combination of chemical vapor deposition, mechanical exfoliation, and other techniques. While each method has its own advantages and disadvantages, advances in technology continue to enable researchers to create larger and more complex ribbons with unprecedented properties. These findings have significant potential applications in fields such as electronics, energy storage, and biomedical devices.

Inquiry us