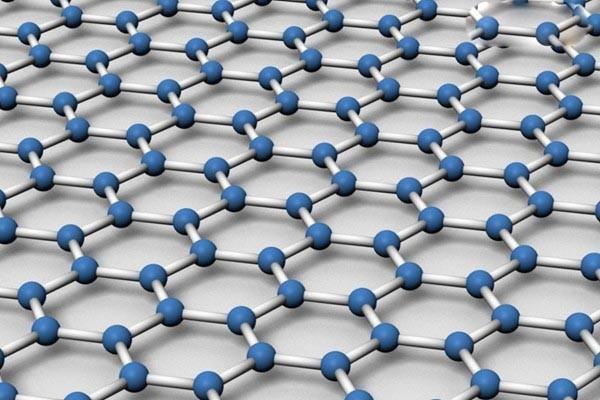

Graphene oxide (GO) is a promising material for various applications, such as electronics, energy storage, and biomedical devices. One way to produce graphene oxide sheets from a starting material is through chemical vapor deposition (CVD), which involves exposing a material to high-temperature carbon dioxide gas and letting it vaporize to form a thin layer of GO on a substrate.

(how to make graphene oxide sheets)

The specific process for CVD of graphene oxide depends on the desired thickness and quality of the sheet. A common method is called a plasma-enhanced chemical vapor deposition (PECVD), which uses a plasma torch to ionize a gas mixture containing carbon dioxide, nitrogen, and hydrogen. The ions are then used to evaporate carbon dioxide onto a metal substrate, where it forms a graphene film.

To make graphene oxide sheets, you will need to start by preparing a suitable substrate material that is compatible with the reaction conditions. This can be a metal, such as aluminum or copper, or a non-metallic material, such as silicon or polyethylene terephthalate (PET).

Once the substrate has been prepared, you can introduce a CO2 atmosphere into the chamber using a pressure gauge and an oxygen source, such as a laser cutter. The CO2 is allowed to react with a reactant material, such as carbon precursors, to form carbon atoms that can later be combined to form graphene.

As the CO2 exposure continues, the carbon atoms can react with other elements in the atmosphere, such as hydrogen, to form glucose molecules. These glucose molecules can then react with oxygen to form glucose-oxidase, a key enzyme involved in photosynthesis. As the reaction proceeds, the carbon atoms can continue to rearrange themselves to form more complex structures, such as graphene sheets.

After the has reached its completion, the graphene sheets can be collected from the substrate using a filter or another means of removing impurities. They can then be processed further if necessary, such as removing surface defects or increasing their thickness.

(how to make graphene oxide sheets)

Overall, making graphene oxide sheets involves a series of chemical reactions that begin when a CO2 atmosphere is introduced to a substrate material. By carefully controlling the reaction conditions and selecting the appropriate materials, you can produce high-quality graphene oxide sheets with controlled properties and potential applications.

Inquiry us