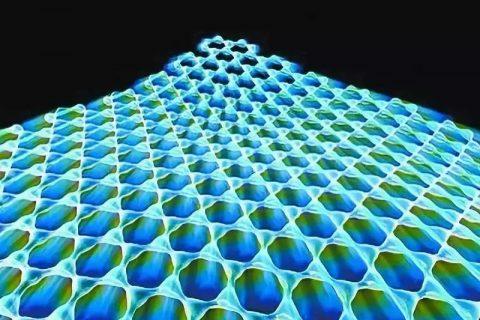

Graphene is a two-dimensional material consisting of carbon atoms arranged in a hexagonal lattice. It has many unique properties, including high strength, high thermal conductivity, and excellent electrical conductivity. While graphene can be prepared using chemical methods, there are also alternative methods that allow for the synthesis of graphene from natural materials.

(how to make graphene sheets)

One method for making graphene is through chemical vapor deposition (CVD), which involves heating a gas, such as nitrogen or argon, to create a layer of graphene on a substrate. This process typically requires the use of specialized equipment, such as a vacuum chamber and a mask, to ensure uniform coverage of the graphene layers.

Another method for making graphene is through physical vapor deposition (PVD), which involves exposing a substrate to a plasma, such as a mixture of neon and argon, to create a layer of graphene on top of it. This process is more gentle than CVD and does not require specialized equipment.

There are also experimental methods for making graphene, such as electrospinning and mechanical exfoliation. Electrospinning involves passing an electric field through a liquid to create thin films of graphene. Mechanical exfoliation involves rubbing a graphene sheet along a surface to remove its surface layer, leaving only the underlying graphene layer.

In addition to these traditional methods, there are also new and emerging approaches to making graphene, such as using living cells and nanotechnology. Researchers have found that certain types of cells can produce large amounts of graphene when they are exposed to various stimuli, such as changes in pH or nutrient levels. Additionally, researchers have developed techniques for using nanotechnology to introduce graphene into different materials, such as using self-assembly principles to create nanoscale arrays of graphene.

Despite these advances, there are still several challenges associated with making graphene at commercial scale. One of the biggest challenges is cost. While some research institutions and companies have made significant progress in this area, the production of graphene is still relatively expensive due to the complexity of the synthesis process and the need for specialized equipment.

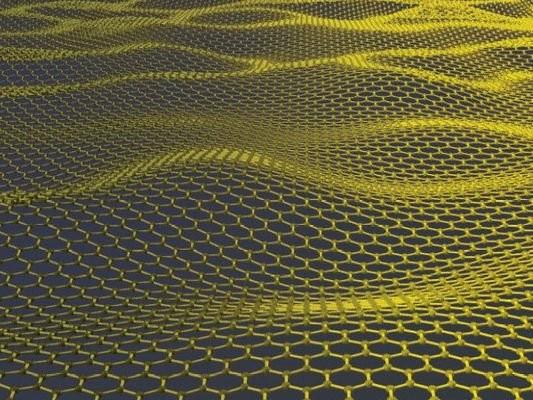

Another challenge is scalability. Graphene synthesis currently involves creating very thin layers of graphene, which can be difficult to control and can lead to defects in the final product. Researchers are working to develop new techniques for producing thicker layers of graphene, as well as ways to improve the yield of graphene during synthesis.

Finally, there are concerns about the environmental impact of graphene production. Some methods for making graphene involve using toxic chemicals, such as boron compounds, which can have negative effects on human health and the environment. There is therefore a need for more sustainable and environmentally friendly methods for producing graphene.

(how to make graphene sheets)

In conclusion, while making graphene is still a challenging task, there are many promising developments and advances in this field. From traditional chemical methods to emerging techniques like electrospinning and mechanical exfoliation, researchers continue to work towards creating a wide range of applications for this versatile and powerful material. As technology continues to advance, we can expect to see even more exciting developments in the field of graphene synthesis in the future.

Inquiry us