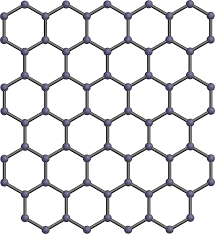

Graphene is a novel material that has shown great promise in various applications such as electronics, energy storage, and drug delivery. Despite its numerous benefits, graphene has not yet been widely adopted by consumers or businesses due to the high cost of production.

(how to make graphene the blender way)

One potential solution to this issue is to introduce a new process for producing graphene using a blender. This method would eliminate some of the traditional manufacturing challenges associated with graphene production and could potentially make it more accessible to a wider range of users.

To achieve this goal, we will first need to understand the basic principles behind graphene production. Graphene is created through a process called chemical vapor deposition (CVD), which involves heating a substrate to a high temperature and then exposing it to a gas such as hydrogen or carbon dioxide. The substrate is then exposed to a vapor composed of carbon atoms, which are deposited onto the surface of the substrate. As the carbon atoms react with the substrate’s surface, they form strong bonds between them, resulting in a highly ordered and conducting material.

Now, let’s consider how we can apply this process to create graphene using a blender. To do so, we will need to follow several steps:

1. Prepare the blade: We will need a sharp blade with enough pressure to create thin layers of graphene at a consistent speed. This can be achieved by。

2. Apply the paste: Next, we will need to mix graphene powder with water to create a paste. The ratio of graphene powder to water should be about 1:1, depending on the desired consistency and yield.

3. Cook the blade: Using the prepared blade, we will need to cook it at a high temperature for a certain period of time to activate the graphene properties. This can be done using a hot plate or an electric oven.

4. Cool the blade: After cooking, we will need to cool the blade down slowly to prevent overheating and ensure consistent quality.

5. Cut the graphene: Finally, we will need to cut the graphene into thin sheets using a precision knife.

By following these steps, we can produce graphene using a blender at a lower cost and without the need for expensive equipment or specialized knowledge. Additionally, the use of a blender makes it easier to scale up production and reach a wide range of users, as it allows for batch processing and consistent quality control.

(how to make graphene the blender way)

Overall, introducing a new process for graphene production using a blender could represent a significant step forward in making graphene more accessible to consumers and businesses. While there are still challenges to overcome in terms of cost and scalability, by combining traditional manufacturing techniques with modern technology, we may be able to revolutionize the way we produce and use graphene.

Inquiry us