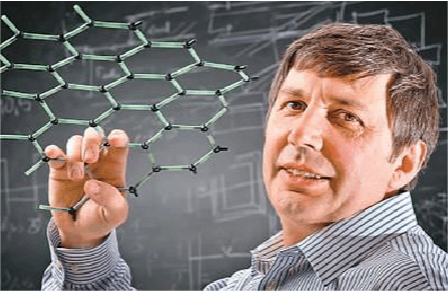

Graphene is a material that has revolutionized many industries, including electronics and energy. It is made from carbon atoms arranged in a three-dimensional lattice structure, which makes it incredibly strong and durable. While there are many ways to produce graphene, one popular method involves using organic oils.

(how to make graphene with organic oils)

In this article, we will explore how to make graphene with organic oils.

Step 1: Choose an Oil

The first step in making graphene with organic oils is to choose the right oil for the purpose. Graphene is sensitive to light, so it should be produced under low-light conditions. Organic oils can provide a good option for this, as they are not as sensitive to light as some other materials.

One common organic oil used in graphene production is hexane, which is extracted from vegetable oils such as sunflower or rapeseed. Hexane is widely available and relatively inexpensive.

Another option is to use coconut oil, which is also extracted from tropical nuts and is known for its high concentration of saturated fatty acids. Coconut oil is less expensive than hexane and may also provide additional benefits to the graphene synthesis process.

It’s important to note that you’ll need to dilute the organic oil with water before adding it to the reaction mixture. This will help prevent the oil from solidifying at the bottom of the reaction vessel and preventing the formation of aggregates during the reaction.

Step 2: Add the Oil to the Reactant

Once you have chosen the appropriate oil for your application, it’s time to add it to the reaction mixture. To do this, carefully pour the oil into the reaction vessel, stirring it gently to ensure that all of the ingredients are evenly distributed.

It’s also important to note that the temperature of the reaction mixture should be maintained between 70-80°C. This range provides the necessary heat for the reactions to occur, but too high or too low temperatures can cause problems.

Step 3: Stir the

After adding the oil to the reaction mixture, it’s important to stir the mixture gently to ensure that all of the ingredients are evenly distributed. The stirring process will help dissolve any excess oil and prevent the formation of aggregates during the reaction.

If the oil is not fully dissolved, you may need to repeat the process until all of the oil is incorporated into the reaction mixture. This may take some trial and error, but with practice, you should be able to achieve the desired results.

Step 4: Monitor the Reaction

As the reaction proceeds, it’s important to monitor the temperature and pressure of the reaction mixture to ensure that it is running smoothly. You may need to adjust the temperature or pressure as needed to maintain optimal conditions.

Additionally, you should check the quality of the graphene product at regular intervals to ensure that it meets your desired specifications. If the graphene is not of sufficient quality, you may need to repeat the process or seek out alternative methods for producing graphene.

(how to make graphene with organic oils)

In conclusion, making graphene with organic oils is a simple and cost-effective process. By choosing the right oil, adding it to the reaction mixture, stirring the mixture gently, monitoring the reaction, and checking the quality of the graphene product, you can produce high-quality graphene without breaking the bank. With some practice, you can even experiment with different oils and methods to create unique and innovative graphene products.

Inquiry us