Title: How to Make Large Graphene Sheets

(how to make large graphene sheets)

Introduction:

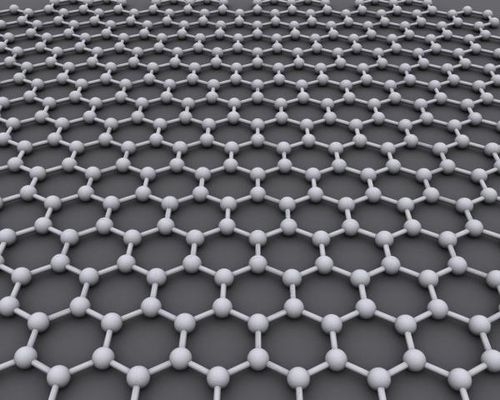

Graphene is an incredibly strong and conductive material, with unique properties that make it ideal for a wide range of applications. One of the most common uses of graphene is in the development of electronic devices such as sensors and transistors. However, making large graphene sheets is not always straightforward. This article will outline the steps involved in creating large graphene sheets without using any special equipment or materials.

Materials:

To make large graphene sheets, you will need two main components: graphene flakes and a metal catalyst. To begin, prepare two sheets of graphene flake using a chemical vapor deposition (CVD) method, which involves heating up a chamber filled with gas and allowing the gases to evaporate from one sheet while remaining on the other. You can also use a mechanical, where you remove the graphene flakes by scratching them off with a sharp tool.

Metal Catalysts:

Once you have two graphene sheets ready, you will need a metal catalyst to accelerate the CVD process and produce larger sheets. There are several types of metals that work well as catalysts for graphene synthesis, including nickel, palladium, and platinum. These metals will help to activate the graphene flakes during the CVD process, causing them to expand and grow in size.

Processing:

To make larger graphene sheets, you will need to carefully control the conditions of your reaction. The temperature and pressure of the gas mixture should be carefully monitored throughout the process, as changes in these parameters can affect the growth rate and quality of the graphene sheets. You may also want to experiment with different gas mixtures or reduce the temperature to minimize surface defects and improve the overall quality of the graphene sheets.

Casting:

Once you have grown the desired number of graphene sheets, you will need to cast them onto a substrate before doing anything else. A substrate is a surface that is suitable for the graphene sheets. Common substrates include silicon wafers, SiGeN substrates, or carbon nanotubes. Choose a substrate that is compatible with the type of graphene used and has a high surface area for efficient transport of graphene layers.

Conclusion:

(how to make large graphene sheets)

Making large graphene sheets is not always easy, but with careful planning and attention to detail, it is definitely possible. By using proper equipment and materials, you can create large graphene sheets without breaking the bank or compromising on their quality. As graphene technology continues to advance, we can expect to see even more innovative applications of this fascinating material in the future.