Title: How to Make Plastic Graphene

(how to make plastic graphene)

Introduction:

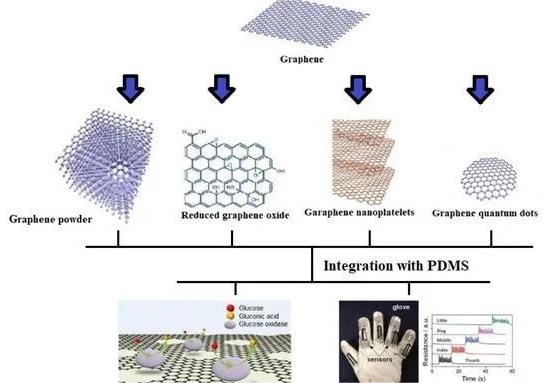

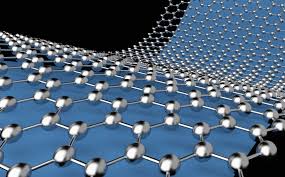

Graphene is a two-dimensional material that has revolutionized the field of materials science and engineering. It’s been predicted to be incredibly versatile, yet its properties remain largely unknown. One of the most promising applications of graphene is in the production of plastics.

Materials and Equipment needed:

1. Graphene samples – Graphene can be extracted from various sources such as spider webs, biological cells, and even sand.

2. Chemical catalysts – To produce plastic using graphene, chemical catalysts are required. These catalysts typically contain metal atoms that donate electrons to form strong bonds between carbon atoms, creating a network of repeating structures called hexagonal boron nitride (BONN).

3. Membrane separator – A membrane separator separates the graphene and BONN layers, allowing the graphene to flow through without contamination.

4. Dielectric polymer – The dielectric polymer layer forms the basis for plastic production. This material must be compatible with the graphene layer and can be made by crosslinking or covalent bonding the polymer molecules to the graphene.

5. Plastic copolymer – Once the desired properties have been achieved, the plastic copolymer can be synthesized using a method known as polyaddition. This process involves adding various monomers to the BONN layer to create the desired plastic composition.

6. Refining and tuning – After the plastic copolymer is formed, it needs to be refined and tuned to ensure optimal properties such as melting point, strength, and flexibility.

Methodology:

The first step is to extract the graphene samples from their natural source. The graphene can be isolated from plant fibers, animal tissues, or even spider webs. Once extracted, the graphene must be separated from the BONN layer, which can be achieved using a membrane separator.

The BONN layer is then crosslinked or covalently bonded to the graphene layer to create the desired plastic structure. The resulting plastic copolymer is then synthesized using a method known as polyaddition. Monomers such as ethylene, propylene, and polyethylene can be added to the BONN layer to create the desired plastic composition.

Refining and Tuning:

Once the plastic copolymer is formed, it needs to be refined and tuned to ensure optimal properties such as melting point, strength, and flexibility. This can be done by adjusting the concentration of monomers used in the reaction or by incorporating additives such as stabilizers, antioxidants, or conductive agents.

It’s also important to evaluate the plastic properties under different conditions, such as temperature, pressure, and humidity, to ensure that the desired properties are maintained throughout the processing process.

Conclusion:

(how to make plastic graphene)

Making plastic from graphene is a complex process that requires specialized equipment and knowledge. However, with advances in technology, this process is becoming increasingly feasible. By combining the unique properties of graphene with other polymers, researchers hope to develop new materials with improved performance and environmental sustainability. As the understanding of graphene and its potential applications continues to grow, we can expect to see more exciting developments in the field of plastic graphene production.

Inquiry us