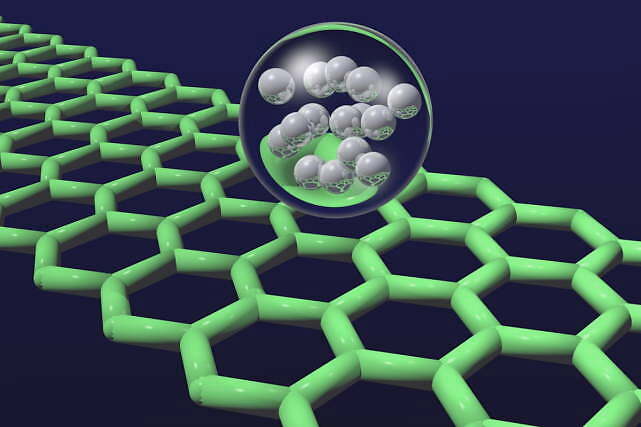

Graphene is an incredibly versatile and promising material that has garnered widespread attention in recent years for its potential applications in electronics, energy storage, and biomedical devices. However, one of the biggest challenges in mass-producing graphene is obtaining high-quality materials from natural sources.

(how to mass produce graphene)

One approach to producing graphene on a large scale is through chemical vapor deposition (CVD), which involves exposing a thin layer of metal or semiconductor material to a plasma of gas at low temperatures. This allows for the formation of graphene through the direct attachment of carbon atoms to the surface of the material. CVD is a widely used method for producing graphene because it is relatively inexpensive and can be scaled up to produce large quantities of material.

Another approach to mass-producing graphene is through mechanical exfoliation, which involves breaking apart graphene layers from a larger piece of material by physical force. This method can be more challenging than CVD due to the sensitivity of graphene to environmental factors such as moisture and oxygen. Mechanical exfoliation is typically performed using a tool called a “piezoelectric probe” or a “vacuum sander”, which apply varying amounts of pressure to break apart graphene layers.

Despite these methods, there are still several challenges associated with mass-producing graphene on a large scale. One of the biggest issues is ensuring that the resulting graphene has the desired properties and characteristics, such as high adhesion strength and high electrical conductivity. Additionally, achieving consistent quality across different batches of material can be difficult due to differences in processing conditions and sample preparation techniques.

Another challenge is reducing costs while increasing yield. While both chemical vapor deposition and mechanical exfoliation have been shown to be effective methods for producing graphene, they require specialized equipment and processes that can be expensive and time-consuming to maintain. To address these challenges, researchers are exploring new approaches to production, such as using non-traditional materials or incorporating graphene into existing manufacturing processes.

(how to mass produce graphene)

In conclusion, mass-producing graphene on a large scale requires a combination of careful experimental design and optimization of processing parameters. While there are several challenges associated with this process, ongoing research is making progress in developing new and efficient methods for producing graphene on a wide range of scales. As the technology continues to advance, we can expect to see even more promising applications for graphene in various industries.

Inquiry us