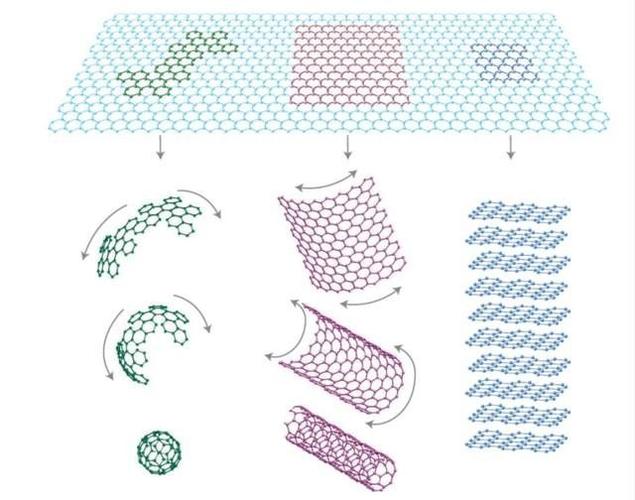

Graphene is a highly conductive material with exceptional mechanical properties, making it an ideal material for various applications such as electronics, energy storage, and nanotechnology. However, graphene has a relatively low surface area which makes it difficult to manipulate at the molecular level.

(how to model graphene on a slab blender vesta)

One approach to creating graphene on a substrate is through a process known as molecular beam epitaxy (MBE). MBE involves vaporizing atoms or molecules in a plasma and directing them onto a substrate to form a graphene layer. This method allows for large-scale production of graphene without the need for specialized equipment.

To perform MBE on a graphene sheet, the substrate must be etched into a specific shape. This can be done using various techniques such as chemical etching or laser-assisted chemical etching. The graphene sheet is then placed on the substrate and allowed to grow under controlled conditions until it forms a single layer of graphene.

Once the graphene layer has formed, it can be used in a variety of ways. For example, it can be used as a matrix for electronic devices, or as a conductive film for energy storage. Graphene can also be used in the manufacture of nanomaterials and materials with unique properties.

However, achieving high-quality graphene films requires careful control over the growth conditions and substrate preparation. In addition, the cost of producing graphene can be prohibitively high due to the complexity of the growth process and the required equipment.

In recent years, there have been several advances in the development of scalable methods for growing graphene films on substrates. One such method is called a microfinishing technique, which involves using a vapor deposition machine to deposit thin layers of graphene onto a substrate. This method allows for more precise control over the size and shape of the graphene films, making it possible to achieve high-quality graphene films with controlled defects and impurities.

Another advancement in the field of graphene growth is the use of covalent bonding methods. These methods involve introducing functional groups or molecules onto the graphene sheet to modify its electronic properties. Covalent bonding methods have shown great promise for improving the performance of graphene-based devices and materials.

In conclusion, graph

(how to model graphene on a slab blender vesta)

I hope this helps! Let me know if you have any other questions.

Inquiry us