Title: How to Produce Sheet Graphene: A Comprehensive Guide

(how to produce a sheet graphene)

Graphene is an incredible material that has gained widespread attention due to its exceptional properties, including high mechanical strength, electrical conductivity, and thermal stability. It is also extremely lightweight, making it ideal for use in various applications such as electronics, aerospace, and medicine. In this blog, we will provide you with a step-by-step guide on how to produce sheet graphene.

Materials needed:

1. Carbon nanotubes (CNTs)

2. Graphene flakes

3. Nonaqueous solutions or detergents

4. Steam pressure

Preparation:

1. Prepare carbon nanotubes: CNTs can be obtained from various sources, such as graphite powders, metal carbide powders, and biological catalysts. However, commercial CNTs tend to have a higher aspect ratio than the desired value of 1/n.

2. Clean the graphene flakes: To obtain high-quality graphene, it is essential to clean the flakes thoroughly using mild detergents and a solution of 1M hydrochloric acid (HCl). The Flakes should be allowed to dry completely before proceeding with the next step.

Making Carbon Nanotubes:

1. Expose graphene flakes to steam pressure: Introduce graphene flakes into a pressure cooker, and heat them at high temperatures, typically between 700°C and 900°C for several hours. The pressure must remain constant throughout the process to ensure complete formation of the nanotubes.

2. Remove excess moisture: After the treatment, remove any excess moisture from the graphene flakes using anhydrous sodium carbonate (Na2CO3) solution or deionized water.

3. Wash the graphene flakes: Rinse the graphene flakes with deionized water and then clean them again using mild detergents.

Forming Nonaqueous Solutions:

1. Preparing nonaqueous solutions: Mix equal parts of methanol and dimethylformamide (DMF) to form a highly nucleating and soluble solution.

2. Coating the graphene flakes: Apply a thin layer of the nonaqueous solution onto each grapheneflake. Ensure that all flakes are coated evenly to maximize their bonding.

3. Store the graphene flakes: Place the coated graphene flakes in a vacuum chamber under conditions close to atmospheric pressure to maintain their structure and prevent decomposition.

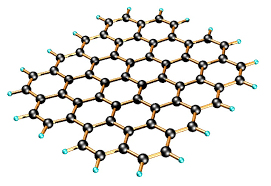

The final product is a sheet graphene film with a highly oriented hexagonal lattice structure. The sheets can be used in various applications, including electronics, energy storage devices, and aerospace engineering. However, further processing and characterization are necessary to optimize the performance of the graphene films. For instance, surface functionalization, cleaning, and intercalation with other materials can enhance the performance of graphene-based devices.

Conclusion:

(how to produce a sheet graphene)

Producing sheet graphene involves a series of steps that require careful preparation and control of the experimental conditions. By following these guidelines, you can successfully create sheet graphene films with desirable properties, making them promising candidates for a wide range of applications in various fields. Future research should focus on optimizing the synthesis methods, improving the quality and functionality of the graphene films, and developing new applications for sheet graphene beyond traditional electronics and energy storage technologies.

Inquiry us