Graphene is a unique material that has revolutionized the field of electronics and nanotechnology due to its exceptional electrical, mechanical, and thermal properties. However, the limited availability of graphene at high concentrations has hindered widespread adoption of this material in practical applications. To overcome this limitation, scientists have developed various techniques for synthesizing graphene from various sources such as metal oxides, carbon nanotubes, and biomass.

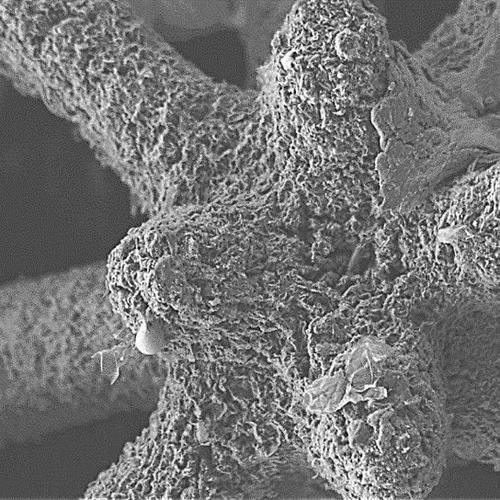

(how to weld graphene together)

One such technique is called chemical vapor deposition (CVD), which involves heating a substrate under high pressure and vacuum to promote the growth of thin films of graphene on top of it. CVD can be used to produce large-scale graphene sheets, but the quality of the resulting graphene depends on several factors, including the substrate material, gas composition, and temperature control. Therefore, careful optimization of these parameters is necessary to obtain high-quality graphene.

Another method for synthesizing graphene is based on mechanical methods such as sintering. In sintering, graphene is formed by melting a precursor material, such as carbon black or titanium dioxide, onto a support material like aluminum or silicon, and then allowing it to cool slowly while under constant pressure. This process can produce graphene with a wide range of properties, including high conductivity, excellent thermal stability, and flexibility.

Another promising method for synthesizing graphene is through chemical reaction-based methods, such as acid electrophilic polymerization (PEP). PEP is a versatile method that can produce graphene from various precursors such as alkali metal hydroxides, aluminide sulfides, and organic compounds. The choice of precursor and reaction conditions can significantly affect the yield and quality of the resulting graphene.

Despite the numerous techniques available for synthesizing graphene, there are still challenges that need to be overcome before graphene can be widely adopted in practical applications. One major challenge is the limited scalability of current synthesis methods. Graphene samples produced using traditional CVD or sintering methods may not have the desired thickness and quality, making them unsuitable for use in certain applications. Moreover, the production of graphene using conventional methods is often energy-intensive and requires specialized equipment and knowledge.

To overcome these challenges, researchers are exploring new methods and architectures for graphene. For example, researchers have developed graphene-based sensors and electronic devices using metal-organic frameworks (MOFs) as a support material. These devices offer a promising avenue for the commercialization of graphene and can be used in a variety of applications, such as monitoring health and environmental parameters, sensing chemical signals, and detecting magnetic materials.

(how to weld graphene together)

In conclusion, graphene is a highly versatile material with unique electrical, mechanical, and thermal properties. However, the limited availability of graphene at high concentrations has hindered widespread adoption of this material in practical applications. To overcome this limitation, researchers are developing various synthesis methods and architectures for graphene, including chemical vapor deposition, mechanical sintering, and chemical reaction-based methods. With continued research and development, graphene has the potential to revolutionize a wide range of industries and applications.