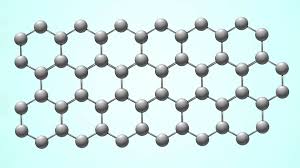

Graphene is a two-dimensional material that has been shown to have remarkable properties, including high strength, thermal conductivity, and durability. It is the thinnest material ever synthesized on Earth, with a diameter of just 1-3 nanometers, making it ideal for use in electronic devices such as transistors and sensors.

(is graphene being made?)

Despite its impressive qualities, there are still many questions about the production of graphene and its potential applications. One of the main challenges facing researchers today is developing scalable manufacturing processes for graphene that can produce large quantities at an affordable price. This is particularly important because graphene has the potential to revolutionize many industries, from electronics to medicine, by enabling new technologies and materials.

Another challenge is ensuring that graphene meets the necessary quality standards for use in electronic devices. Graphene must be free of defects and impurities that could affect its performance or lifespan. To address these issues, researchers are developing methods for identifying and removing defects from graphene before it is used in practical applications.

In addition, graphene’s unique properties make it useful in a wide range of applications beyond electronics. For example, it could be used to create new types of energy storage systems, such as batteries or supercapacitors, which would be more efficient and durable than traditional technologies. Graphene also has potential uses in medicine, such as as a replacement for current surgical instruments that may cause complications.

Despite these exciting possibilities, graphene’s production remains a major challenge. Researchers are still working to develop scalable manufacturing processes that can produce large quantities of graphene at an affordable price. Additionally, there is ongoing research into improving graphene’s properties to make it even more effective and versatile.

One approach that researchers are exploring is the use of catalysts to accelerate the synthesis process of graphene. Catalysts are substances that help to speed up chemical reactions and can improve the efficiency of a wide range of industrial processes. By using a catalyst, researchers hope to increase the productivity of their manufacturing processes and reduce the cost of producing graphene.

Another approach is the use of surface engineering techniques to modify the structure of graphene and enhance its properties. For example, researchers have used chemical etching to remove impurities from graphene and improve its electrical conductivity. They have also used self-assembly techniques to create specific patterns on graphene that can be used to optimize its performance.

(is graphene being made?)

In conclusion, while graphene is still a relatively new technology, its potential applications are vast and promising. However, there are still many challenges that need to be overcome before graphene can become a widely used material. Through continued research and development, we can expect to see widespread adoption of graphene in the coming years, transforming many aspects of our lives.

Inquiry us