“Unleash the Unveiled Power of Tungsten Carbide: A Comparative Analysis”

(Is Tungsten Carbide Stronger Than Steel?)

Are you ready to uncover the awe-inspiring strength of tungsten carbide? Then, read on for an exciting exploration into this fascinating material.

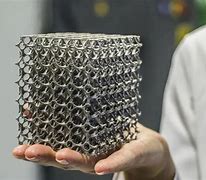

Tungsten carbide is known for its unparalleled durability and resilience, making it a top choice for applications that require robustness and resistance to wear and tear. In this post, we’ll delve into the comparison of tungsten carbide and steel, examining their respective strengths and weaknesses to help you make an informed decision.

Firstly, let’s take a closer look at the composition of tungsten carbide. Unlike steel, which contains iron, carbon, and manganese, tungsten carbide consists only of tungsten and carbon. This unique combination provides the necessary mechanical properties for cutting, grinding, and, making it an ideal choice for applications where precision and accuracy are essential.

Another key factor to consider when comparing tungsten carbide and steel is their workability. Tungsten carbide is highly malleable and can be shaped and formed in a variety of ways, making it ideal for use in demanding industries such as aerospace, automotive, and construction. On the other hand, steel is typically harder than tungsten carbide, which means it requires more force to deform or cut effectively.

In terms of heat resistance, both tungsten carbide and steel have excellent thermal conductivity, allowing them to withstand high temperatures without degrading. However, this difference in temperature tolerance means that tungsten carbide may be more suitable for applications where exposure to extreme heat is critical, such as in welding and manufacturing processes.

Finally, let’s consider the cost of each material. While steel can be a more expensive option due to its higher tensile strength and thermal conductivity, tungsten carbide offers significant cost savings over time, especially if purchased in bulk. This makes it a popular choice for applications where cost-effectiveness is a priority, such as in dental equipment and electronics.

(Is Tungsten Carbide Stronger Than Steel?)

In conclusion, while there are certainly some differences between tungsten carbide and steel when it comes to performance and workability, these don’t make either material any less strong or valuable. Both materials offer exceptional durability, reliability, and cost savings, making them ideal choices for a wide range of applications. So the next time you’re considering purchasing a new material, remember that there are many factors to consider beyond just the surface appearance – like their chemical composition, workability, and cost effectiveness – and that ultimately, the right material will depend on your specific needs and goals.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)