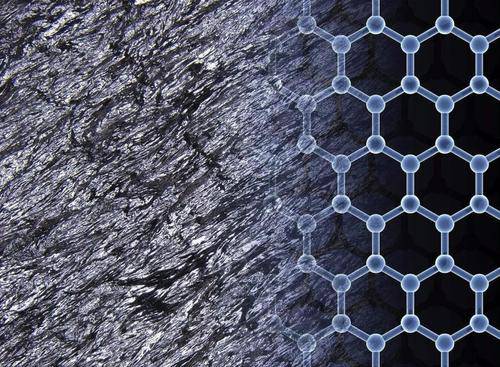

Defects in graphene oxide refers to small-scale deviations or irregularities in the structure and/or composition of the material that can affect its physical, chemical, and electrical properties.

(what is the meaning of defected samples in graphene oxide)

Graphene oxide (GO) is a two-dimensional materials composed of carbon atoms arranged in a hexagonal lattice. It has several unique properties that make it an ideal material for various applications such as energy storage, electronics, and drug delivery systems. However, like any other material, GO has its own set of defects that can affect its performance.

One of the most common types of defects in GO is defects in the graphene sheet. Defects can be caused by factors such as impurities, edge bonding, and stress. These defects can reduce the sheet’s thickness, mechanical strength, and thermal stability, which can negatively impact GO’s performance in specific applications.

Another type of defect in GO is defects in the layer structures. The layers in GO are stacked on top of each other, and each layer contains a single layer of graphene. Defects in the layer structures can cause inter-layer interfaces to become unstable, leading to reduced oxygen-reduction capacity and improved fuel cell efficiency.

In addition to these defects, there are also structural defects in GO, such as wrinkles and cracks. Structural defects can affect GO’s porosity and surface area, which can influence its adsorption properties and stability.

To control and prevent defects in GO, researchers have developed various techniques such as chemical vapor deposition (CVD), mechanical exfoliation, and ion implantation. CVD involves heating the graphene sheet under high pressure to create thin layers, while mechanical exfoliation involves breaking down the graphene sheet into smaller flakes using mechanical force. Ion implantation involves injecting ions into the graphene layer to remove or modify defects.

Despite these techniques, defects in GO still pose challenges in practical applications. For example, removing defects from a large-scale graphene production plant can be expensive and time-consuming. Moreover, controlling defects within a small-scale device, such as a fuel cell, is critical for achieving optimal performance.

(what is the meaning of defected samples in graphene oxide)

In conclusion, defects in graphene oxide can significantly affect its performance in various applications. Researchers continue to develop new methods to control and prevent defects in GO to improve its properties and overcome these challenges. With further advancements in materials science and engineering, we can expect to see even more innovative applications of graphene oxide in the future.

Inquiry us