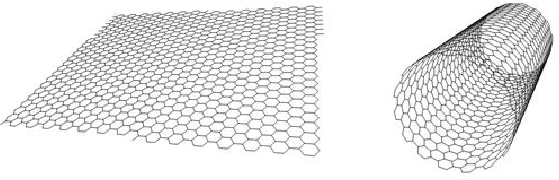

Graphene is a two-dimensional material that has gained significant attention in recent years due to its unique properties, including high electron mobility, electrical conductivity, and thermal stability. However, the use of graphene as a material in electronic devices has been limited by concerns about its cost, scalability, and fragility.

(what s spin and valley degenreacy in graphene)

One of the key issues in using graphene for electronic applications is its low melting point. Graphene is known to form strong intermolecular interactions and can easily break down at room temperature or even under normal conditions. This means that it must be carefully processed and stored before being used, which can limit its potential applications.

Another issue is the lack of scalability in current graphene-based electronic devices. While research has shown promise in creating graphene-based transistors, sensors, and batteries, they have not yet reached commercial scale. This is due in part to the challenges associated with growing large quantities of graphene on a large surface area.

Valley degeneration is another concern in using graphene for electronic devices. Valley degeneration refers to the loss of electronic functionality in a material due to the presence of impurities or defects in the material’s structure. Graphene, like many other materials, can exhibit valley degeneration if it contains certain types of impurities, such as oxygen atoms or carbon nanotubes. This can limit the range of electronic functions that can be achieved using graphene-based electronics.

Despite these challenges, researchers are making progress in developing graphene-based electronic devices. One promising approach is to introduce chemical defects into graphene to create heterostructures that can improve the performance of the material. These defects can include defects in the graphene sheet itself, as well as defects introduced by external sources, such as chemical vapor deposition (CVD) or physical vapor deposition (PVD).

Another approach is to use non-diamond bonding methods, such as chemical vapor deposition (CVD), to grow graphene on metal substrates. CVD involves exposing a metal substrate to a gas or vapor containing carbon molecules, which can promote the growth of graphene sheets on the substrate. By adjusting the parameters of the process, researchers can control the quality and size of the graphene films produced.

(what s spin and valley degenreacy in graphene)

Overall, while there are still challenges associated with using graphene for electronic devices, researchers are making progress in overcoming these limitations. As technology continues to advance, we may see more widespread adoption of graphene-based electronics in the future.

Inquiry us