What is sodium silicate?

The modulus of sodium silicate is n=SiO2/Na2O; the modulus shows the composition of sodium silicate, which is an important parameter of sodium silicate, generally between 1.5 and 3.5. The greater the modulus of sodium silicate, the more difficult it is to dissolve solid sodium silicate in water; n is 1. Often, warm water can be dissolved, n is increased by hot water to dissolve, and n is greater than 3 requires more than 4 steam atmospheres. The greater the modulus of sodium silicate, the more the Si content, the higher the viscosity of sodium silicate, the easier it is to decompose and harden, the greater the bonding force and the different modulus of sodium silicate polymerization degree is different, resulting in the hydrolysis of its products have important impact on the production and application of silicate components are also significant differences, so the different modulus of sodium silicate has different uses.

Classification of sodium silicate

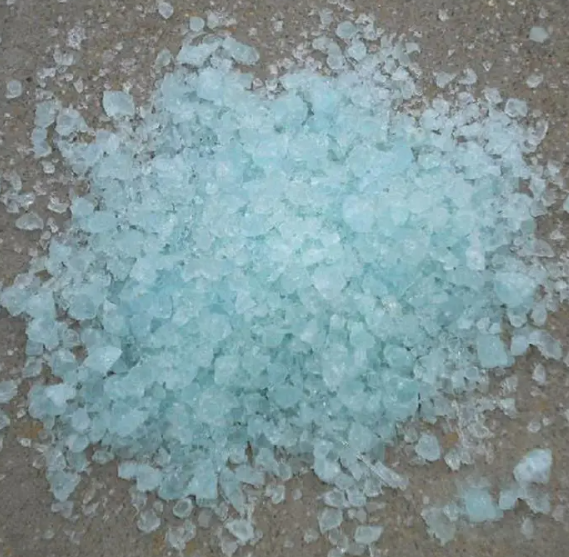

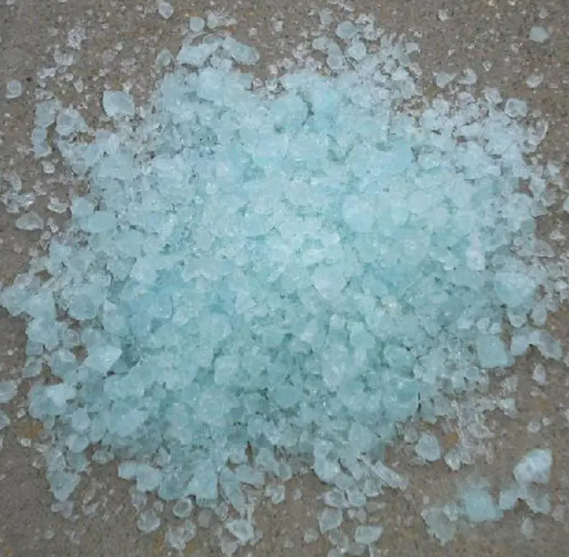

According to the physical state, it can be divided into two categories: liquid sodium silicate and solid sodium silicate. Liquid sodium silicate: liquid Na2O·nSiO2 is distinguished according to the different proportions of quartz sand and alkali and different types of alkali, the appearance of viscous liquid, different grades of color have obvious differences, from colorless change to gray black. There are ① neutral Na2O·nSiO2, ② basic Na2O·nSiO2, ③ weakly basic Na2O·nSiO2, ④ compound Na2O·nSiO2. Solid sodium silicate: Solid Na2O·nSiO2 is an intermediate product with a mostly light blue appearance. Na2O·nSiO2 formed by dry casting is massive and transparent, while Na2O·nSiO2 formed by water quenching is granular and can be used only when converted into liquid Na2O·nSiO2. Common Na2O·nSiO2 solid products are ① bulk solid, ② powdered solid, ③ instant sodium silicate, ④ zero water sodium metasilicate, ⑤ sodium pentahydrate metasilicate, ⑥ sodium orthosilicate.

The use of sodium silicate

Sodium silicate is the most valuable filler in the soap-making industry. It can be used as a filler for paper making. Used in the manufacture of silicone gel and silica gel. Used in the casting industry as a binder, bonding sand and clay to make various molds and cores that people need.

Production method of sodium silicate

Sodium silicate has two production processes: the dry method and the wet method. The dry method includes sodium carbonate, sodium sulfate (sodium sulfate), and sodium chloride. The liquid soda ash and quartz sand were used as raw materials in the wet process, and the liquid product was obtained after the heating and pressurizing reaction. Sodium carbonate method: According to the modulus requirements of the required product, the soda ash (Na2CO3) and the quartz sand (SiO2) with a particle size of 0.180 ~ 0.250mm (60~80 mesh) are mixed evenly in proportion to the horseshoe flame kiln, and melted at 1450~1500℃, and the high-temperature molten product flows out of the kiln outlet. Pressed into blocks or water quenched into particles by rollers above the mold. Sodium sulfate (also known as sodium sulfate, anhydrous glauberite) method: raw materials include sodium sulfate (anhydrous glauberite), carbon powder, and quartz sand; the production process and sodium carbonate method is the same; the difference is that the furnace uses negative pressure operation, after the kiln ventilation. Sodium chloride method: Using sodium chloride (NaCl) and quartz sand as raw materials, the quartz sand and sodium chloride are mixed evenly and melted, and the steam is passed into the reaction to obtain sodium silicate and hydrochloric acid. This method has a slow reaction speed and is not used in general factories. Wet method: the liquid sodium hydroxide and quartz sand are mixed into the autoclave in the appropriate proportion, heated by steam, and stirred so that it directly reacts into liquid sodium silicate, filtered, and concentrated to produce the finished water glass. The production of liquid sodium silicate by wet method only accounts for 5% of the total production in China.

Price of Sodium silicate

Sodium silicate particle size and purity will affect the product’s Price, and the purchase volume can also affect the cost of Sodium silicate. A large amount of large amount will be lower. The Price of Sodium silicate is on our company’s official website.

Sodium silicate supplier

If you are looking for high-quality, high purity and cost-effective sodium silicate, or you need lastest price of sodium silicate, feel free to send an email to contact mis-asia. It has more than 12 years of experience providing ultra-high quality chemicals and nanotechnology materials, including foam concrete, nitride powder, graphite powder, sulfide powder, and 3D printing powder